Gecko-inspired Synthetic Adhesive (GSA)

| News |

|

|

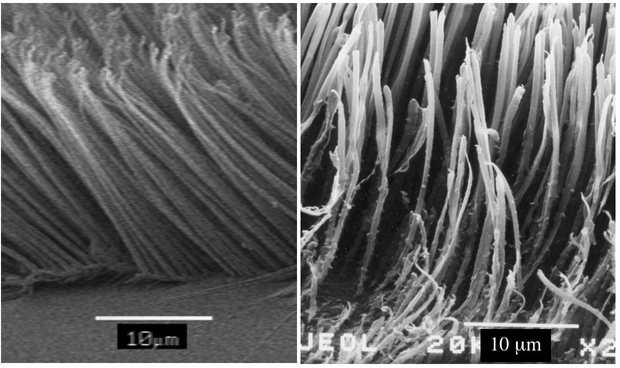

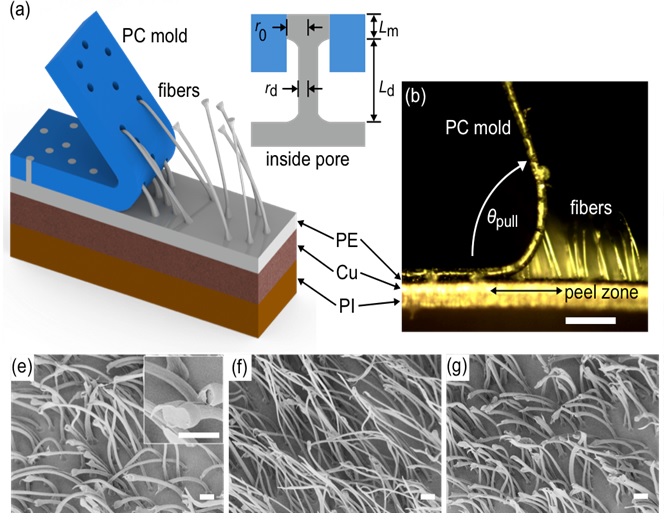

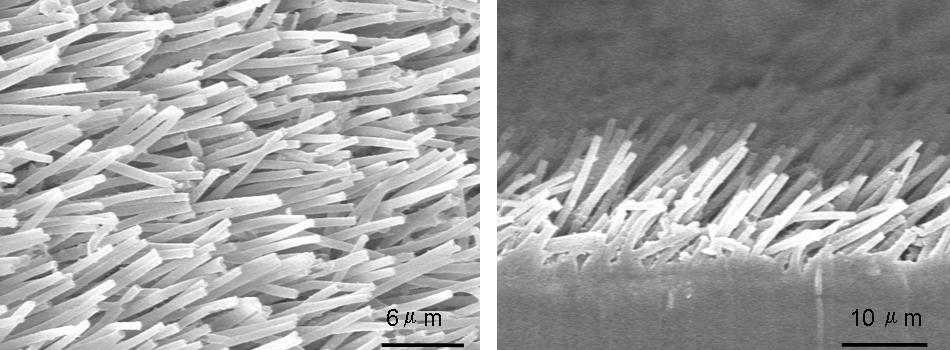

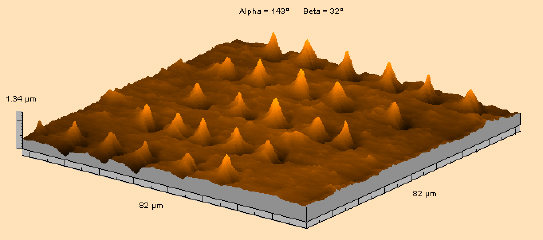

Low-modulus micro fiber arrays (May 2014) We produced high-aspect-ratio, angled polymer microfiber arrays by directional pulling of polyethylene from low-aspect-ratio, microporous polycarbonate templates. These arrays represent a novel substrate for electrostatic sensors and actuators because they are characterized by low stiffness (<24 kPa effective elastic modulus), low Poisson's ratio (effectively zero at low strains), and very low density (<1% of solid polyethylene). Angled microfiber arrays as low-modulus, low Poisson's ratio compliant substrates, J. Micromech. Microeng. 24 065016, 2014. |

|

|

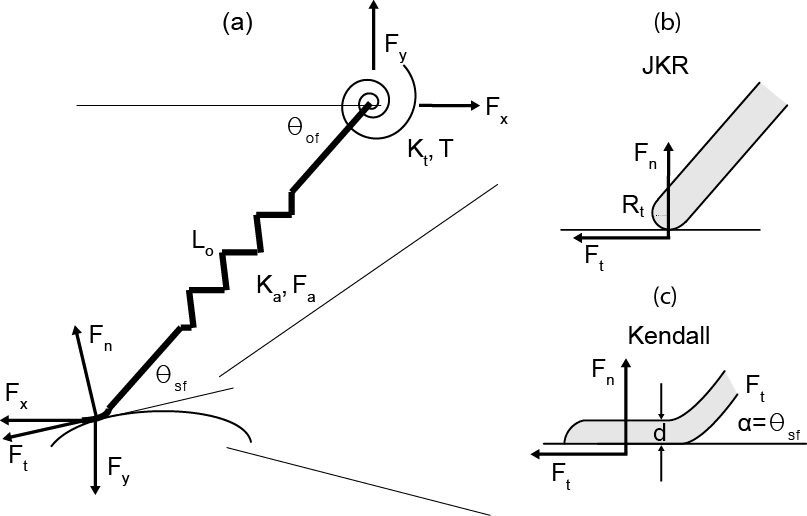

GSA shearing on rough surfaces (April 2014) A model for the relationship between surface feature size and the adhesive terminal feature shape was developed. On sinusoidal surfaces with amplitudes much larger than the nanoscale features, spatula-shaped features can increase adhesive forces by 2.5 times on smooth surfaces and 10 times on rough surfaces. Simulation of synthetic gecko arrays shearing on rough surfaces, J. R. Soc. Interface, April 2014. movie |

|

|

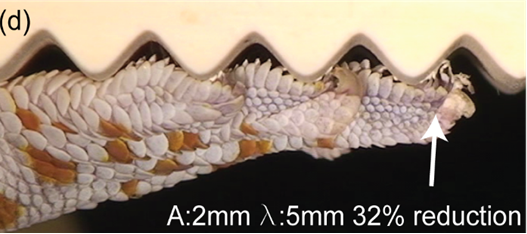

Gecko Toe on Rough Surfaces (Oct. 2013) We measured the maximum shear force a gecko foot can attain on sinusoidal patterns in sizes similar to the dimensions of the toes and lamellae structures. We found shear adhesion significantly decreased on surfaces that had amplitudes and wavelengths approaching the lamella length and inter-lamella spacing, losing 95% of shear adhesion over the range tested. Gecko toe and lamellar shear adhesion on macroscopic, engineered rough surfaces, J Exp Biol, October 2013. |

|

|

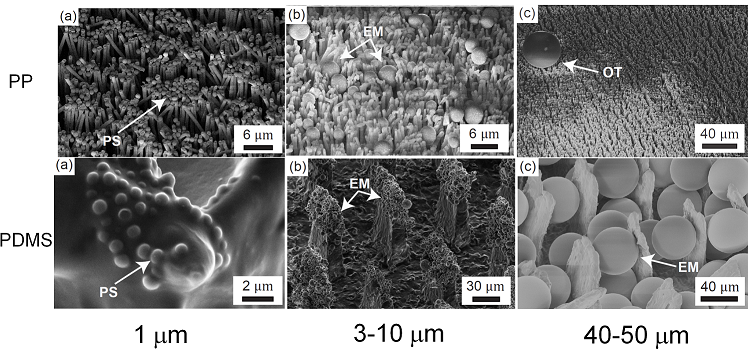

Hard vs Soft Fibrillar Self-cleaning (June 2013) For certain particle sizes and fiber diameters, both hard (polypropylene) and soft (silicone rubber) fibrillar adhesives can recover adhesive capabilities after fouling with spherical particles. An analysis of the contact strength between fibers, particles and substrates reveals that dry self-cleaning is more effective for smaller fiber diameters and smaller loss functions, such as hard thermoplastics. Dry Self-Cleaning Properties of Hard and Soft Fibrillar Structures, ACS Applied Materials and Interfaces, June 2013 (just accepted) |

|

|

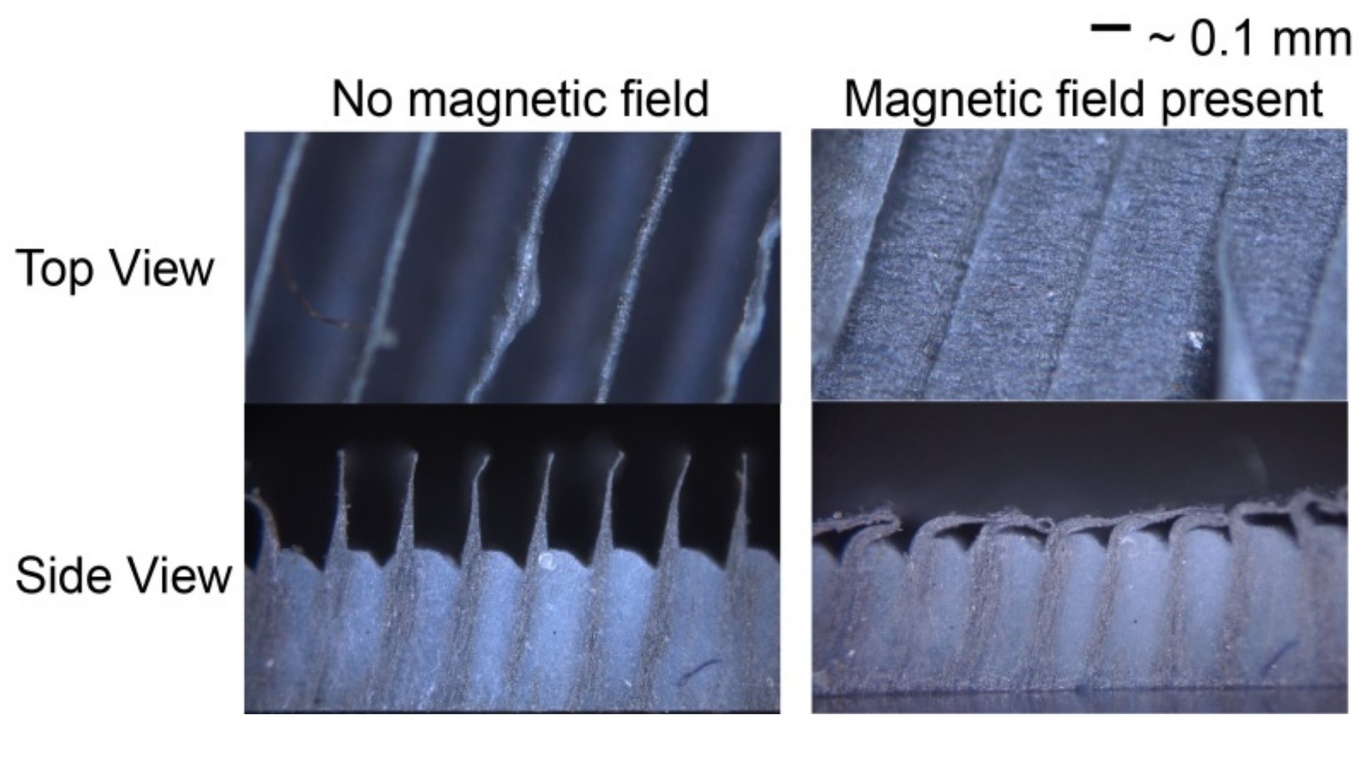

Controllable Particle Adhesion (Feb. 2013) Controllable adhesion to glass spheres with a magnetically actuated synthetic gecko adhesive is demonstrated. Results show sphere pull-off forces can be increased 10-fold by changing the ridge orientation via the external magnetic field, and that the effective elastic modulus can be changed from 65 kPa to 1.5 MPa. Controllable particle adhesion with a magnetically actuated synthetic gecko adhesive, Advanced Functional Materials, 2013 |

|

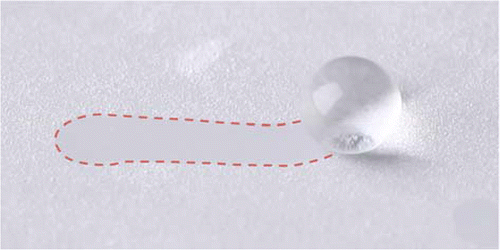

| Wet Cleaning of HDPE GSA

(Oct. 2012) Hard-polymer-based GSA formed with high-aspect-ratio microfibers from high-density polyethylene (HDPE) self-cleans with water. The microfiber adhesive shows almost complete wet self-cleaning of dirt particles with water droplets, recovering 98% of the adhesion of the pristine microfiber adhesives. Wet Self-Cleaning of Superhydrophobic Microfiber Adhesives Formed from High Density Polyethylene, Langmuir, 2012 |

|

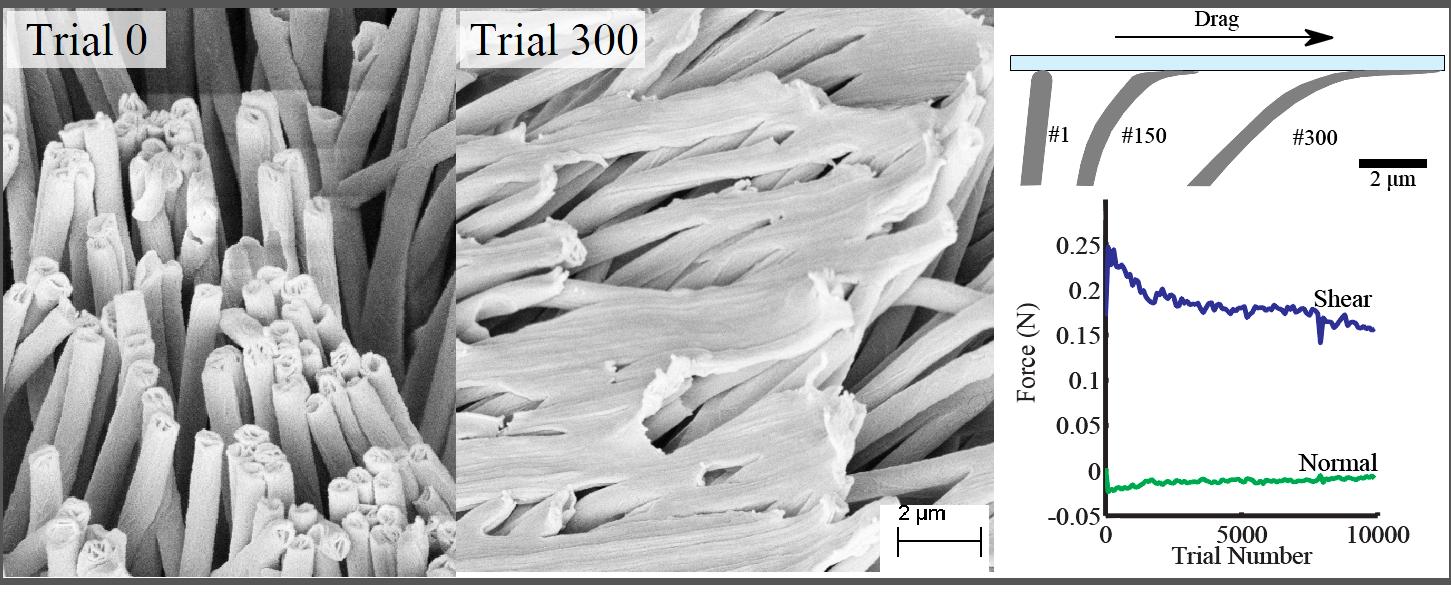

| GSA Adhesive Material

Limits (Aug. 2011) HDPE and PP fibrillar arrays have shear adhesion stress (0.3 MPa) sufficient to deform the fibers. Hence the fiber material strength is a limit to greater adhesion strength. Surprisingly, the GSA maintained 54% of original stress in spite or marked deformation over 10,000 cycles. Shear Adhesion Strength of Thermoplastic Gecko-Inspired Synthetic Adhesive Exceeds Material Limits, Langmuir, 2011 |

|

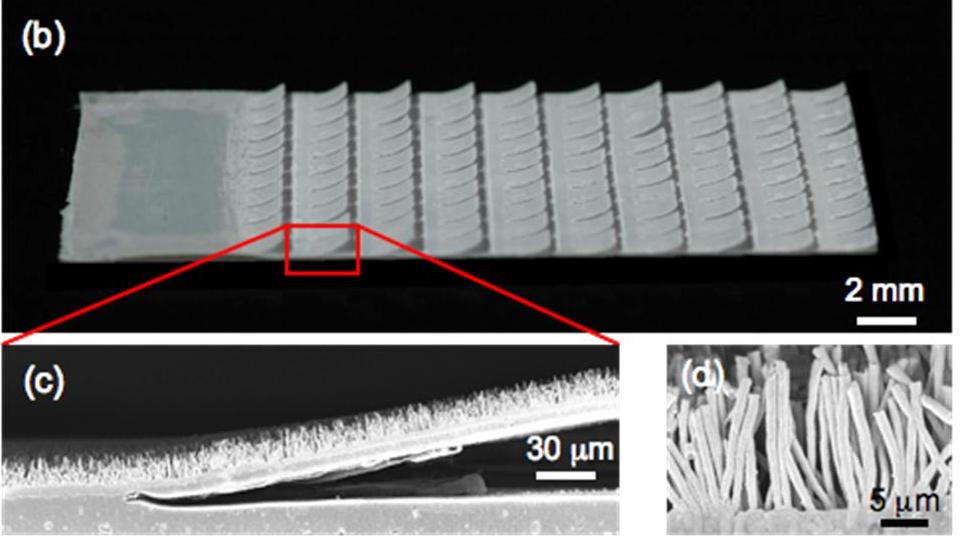

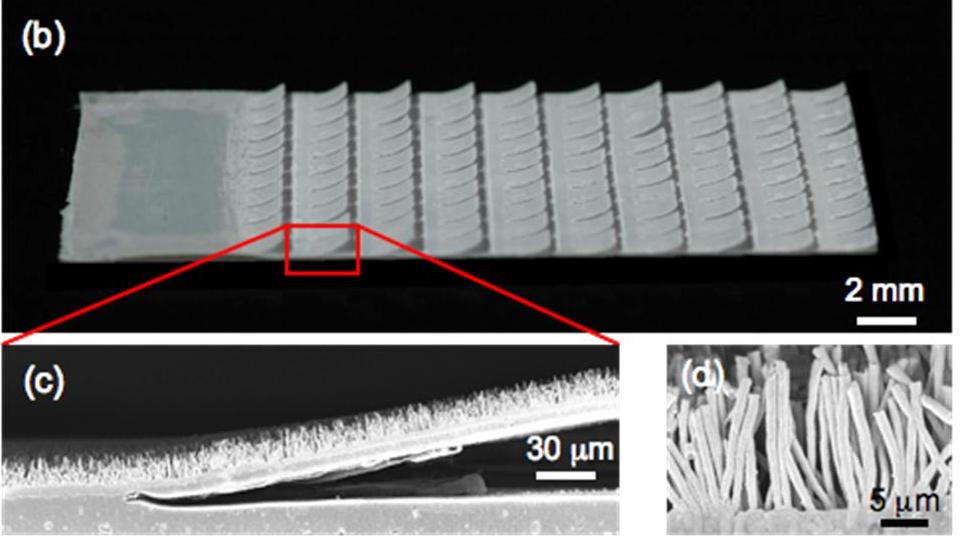

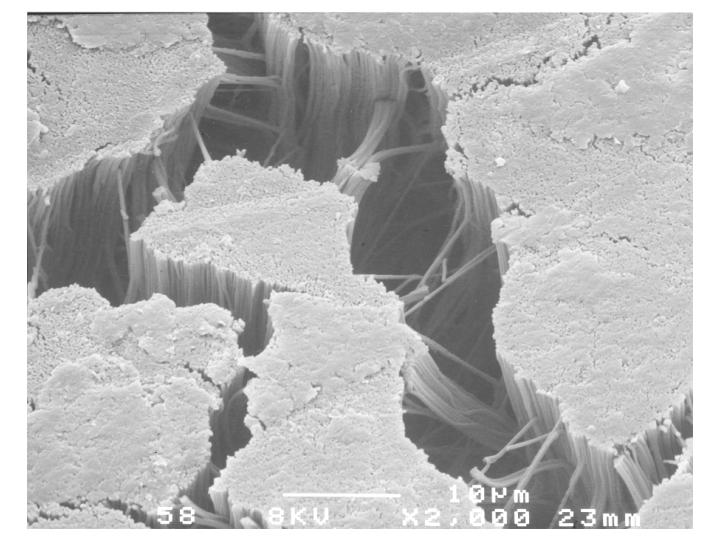

| Combined Lamellar

Nanofibrillar Array (Oct.

2009) Lamellar

structures act as base support planes for high-aspect ratio HDPE fiber

arrays. Nanofiber arrays on lamella can adhere to a smooth grating with

5 times greater shear strength than flat nanofiber array. Langmuir, Oct 2009

|

|

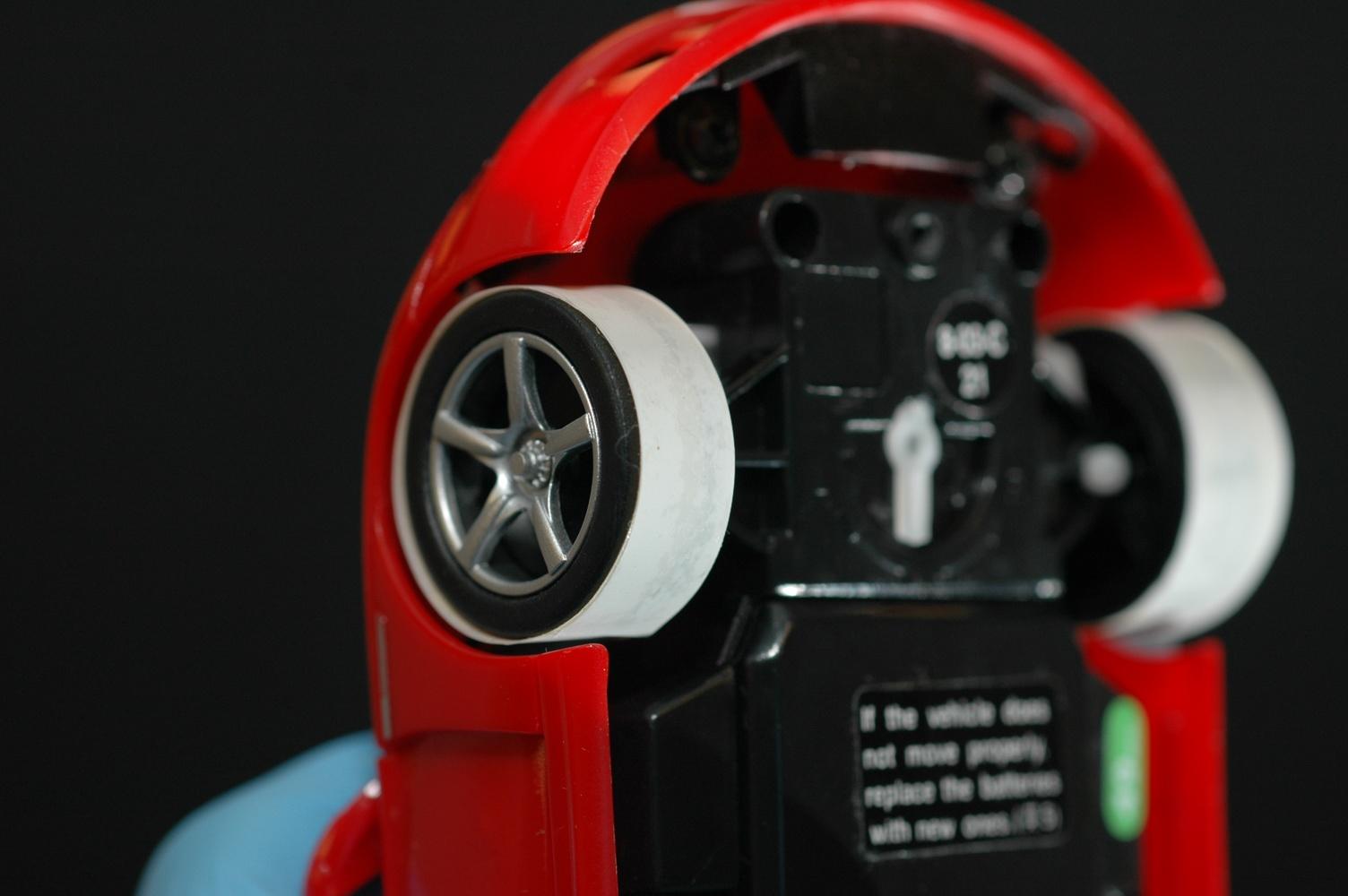

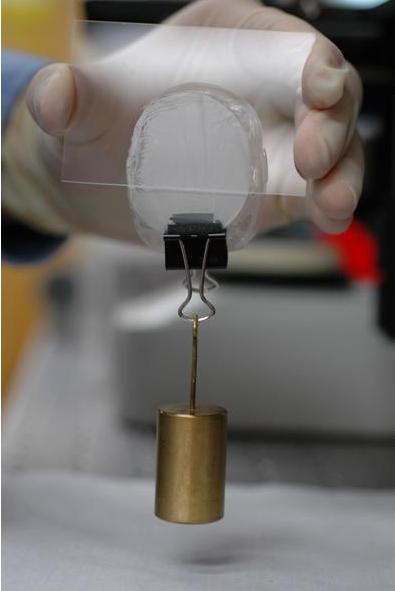

| Gecko Tire for Model

Car (Nov. 2008) Microfiber

array wrapped on model car tire demonstates high friction. (Note: so

far, tire only works on smooth surfaces.)

|

1/18 scale model car with gecko tires on acrylic sheet. |

|

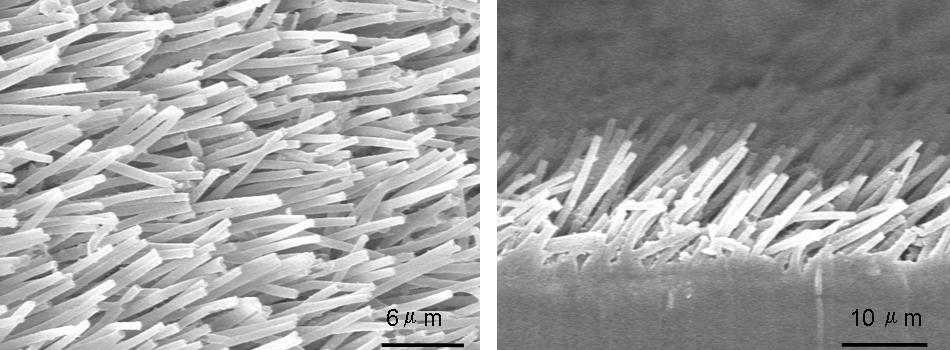

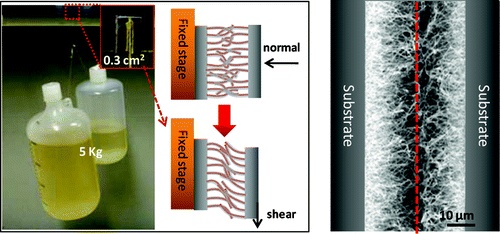

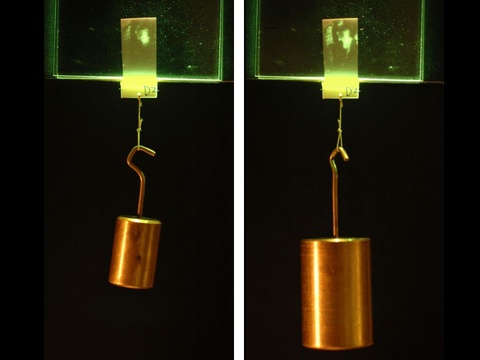

Directional Adhesion of Angled Microfibers

(Nov. 2008)

Angled polypropylene

microfibers show strong directional adhesion effects, with shear

strength in direction of fibers 45

times larger than sliding against

fiber directions. A 1 sq. cm. patch supported a load of 450 grams in

shear. Directional

adhesion of gecko inspired angled microfiber arrays, Applied Physics Letters, 2008. |

|

|

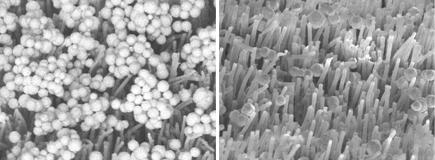

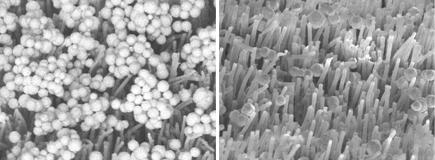

Self

Cleaning Gecko Adhesive (Sep. 2008)

First

synthetic gecko

adhesive which cleans itself during use, as the natural gecko does.

After contamination by microspheres, the microfiber array loses all

adhesion strength. After repeated contacts with clean glass, the

microspheres are shed, and the fibers recover 30% of their original

adhesion. The fibers have a non-adhesive default state, which

encourages particle removal during contact. Contact Self-Cleaning of Synthetic Gecko

Adhesive, Langmuir 2008 |

Before and after repeated contacts. |

| Overview of Gecko Adhesion Project |

|

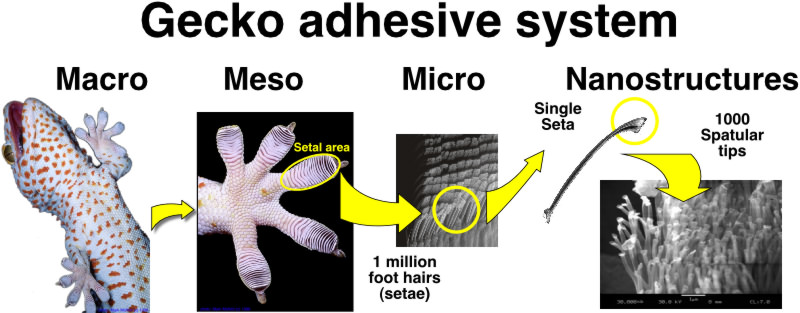

| Geckos

have the remarkable ability to run at any orientation

on just

about any smooth or rough, wet or dry, clean or dirty surface. The

basis for geckos' adhesive properties is in the millions of

micron-scale setae on each toe of the gecko form a self-cleaning dry

adhesive. The tip of each seta consists of 100 to 1000 spatulae only

100 nanometers in diameter. Our interdisciplinary team of biologists

and engineers has been working since 1998 developing models for how the

natural

nanostructures function in a hierachical combination of spatulae,

spatular stalks, setal stalks, setal arrays, and toe mechanics, and

developing nanofabrication processes which allow large arrays

of hair patches to be economically fabricated. Keywords: synthetic gecko adhesion, gecko adhesive, gecko tape |

|

Interesting Facts about Gecko Adhesion

-

Gecko toes are not ``sticky'' like tape.

If you touch a gecko toe it feels soft and smooth, and not sticky at all. If you pressed a gecko toe onto a hard surface it would not stick. The toe will only adhere when the microfibers (setae) are engaged, by dragging or sliding the toe parallel to the surface. (If toes were sticky like tape, it would be difficult for a gecko to walk or run, as it would be too hard to pull its feet up.)

There are many groups starting to work on ``gecko-inspired'' adhesive materials. A summary of the main results are given in synthetic gecko adhesive comparison . It is important to note that the natural gecko adhesive is characterized by very low preloads and peel strength, which is needed for climbing. (Much of the synthetic work is aimed at achieving different characteristics than the natural gecko adhesive, such as large normal forces.) A brief synopsis of the history gecko-inspired synthetic adhesives is here.

| Progress in Gecko-inspired Synthetic

Adhesion |

|

| Combined Lamellar

Nanofibrillar Array (Oct. 2009) Lamellar

structures act as base support planes for high-aspect ratio HDPE fiber

arrays. Nanofiber arrays on lamella can adhere to a smooth grating with

5 times greater shear strength than flat nanofiber array. Langmuir, Oct 2009

|

|

|

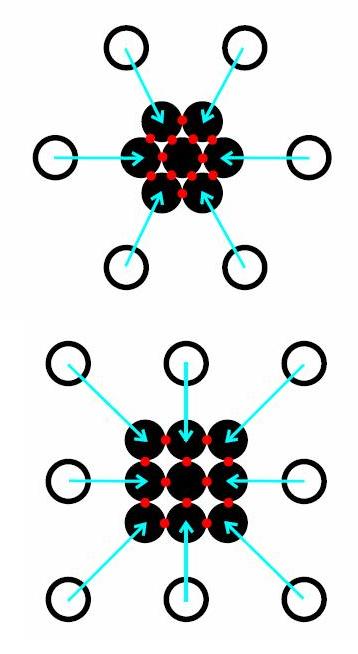

Hybrid CoreShell Nanowire Connectors (April 2009)

Arrays of parylene coated

Ge nanowires connect with themselves to form a reusable connector.

Uniquely, NW chemical connectors exhibit high macroscopic shear

adhesion strength (1.6 MPa) with minimal binding to non-self-similar

surfaces, anisotropic adhesion behavior (shear to normal strength

ratio 25), low preloading, reusability, and efficient

binding for both micro- and macroscale dimensions.

Nanoletters,

April 2009 |

|

|

Reduced Resistance Nanowire Contacts (Dec. 2008)

Nickel nanowires can

increase the true area of contact and reduce contact resistance.

Resistance between a probe and an array of 200 nm by 10 micron nickel

nanowires was reduced by an order of magnitude compared to contacting a

flat sheet.

Reducing contact resistance using compliant nickel nanowire arrays,

IEEE Trans. on Comp. and Pack. Tech. 2008.

|

|

|

Directional Adhesion of Angled Microfibers

(Nov. 2008)

Angled polypropylene

microfibers show strong directional adhesion effects, with shear

strength in direction of fibers 45 times larger than sliding against

fiber directions. Angled fibers also show normal adhesion without shear

load, unlike vertical fibers. Directional

adhesion of gecko inspired angled microfiber arrays, Applied Physics Letters, 2008. |

|

|

Self Cleaning Gecko Adhesive (Sep. 2008)

First

synthetic gecko

adhesive which cleans itself during use, as the natural gecko does.

After contamination by microspheres, the microfiber array loses all

adhesion strength. After repeated contacts with clean glass, the

microspheres are shed, and the fibers recover 30% of their original

adhesion. Contact

Self-Cleaning of Synthetic Gecko Adhesive, Langmuir 2008 |

|

|

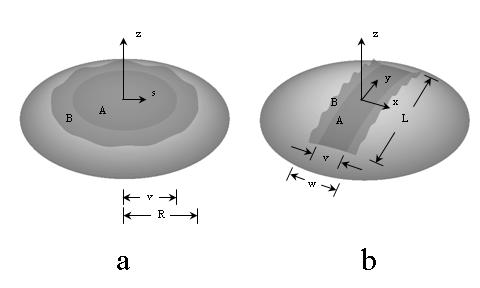

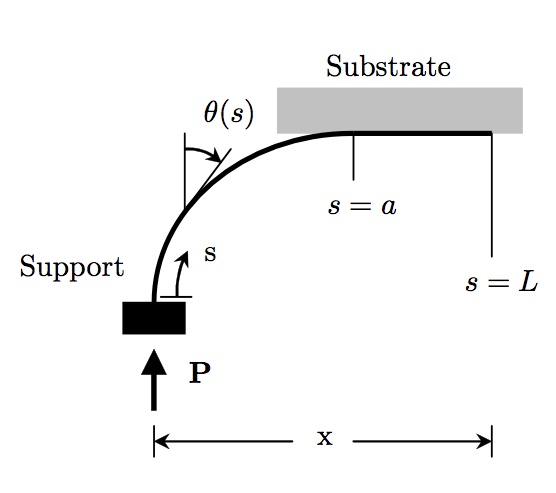

Adhesion of Elastic

Plate to a Sphere (Feb. 2008)

Adhesion of even a thin

membrane to a non-developable surface, such as a sphere, requires

stretching as well as bending. Dividing contacts into small plates

reduces membrane strain and increases adhesion.Adhesion of an elastic plate to a sphere, Proc. Royal Soc. A 2008 |

|

|

Directional

gecko adhesive (Jan. 2008)

First easy attach, easy release, and directional synthetic

gecko adhesive using hard polymer microfibers. Microfiber array using

42 million polypropylene microfibers per square centimeter. Patches

can support 9 N/sq.cm. in estimated contact region with preload of just

0.1N/sq.cm.Sliding-induced adhesion of stiff polymer, Interface 2008 |

|

|

Shear adhesion from polypropylene

microfibers (2007)

Shear adhesion of 0.1 N/sq.cm. using 0.6 micron polypropylene fiber

array. Normal preload required was less than 0.05 N/sq. cm [Schubert et

al. Jnl. of Adhesion Sci. and Tech. 2007]. |

|

| High friction from polypropylene microfibers

(2006) Using an array of vertically

oriented polypropylene microfibers, high friction is demonstrated

without using a soft/sticky material. At 0.8 N/sq. cm, coefficient of

friction is greater than 5.

[Majidi et al PRL 2006 ]. Copyright (2006) by the American Physical Society High friction from a stiff polymer using micro-fiber arrays, Phys. Rev. Letters, 2006 |

|

|

Side contact model for fiber adhesion (2005)

Analysis of fiber adhesion in side contact. [Majidi, Groff, Fearing J. Appl. Phys 2005] shows that sufficiently long fibers, e.g. carbon nanotubes can stably make side contact. This side contact can give 10-20 times greater adhesion force than a hemispherical tip contact. |

|

|

Verification of side-side contact clumping

(2004)

Fiber density is limited by clumping- both tip-tip at larger gaps between fibers and side-side for closer fibers. A square lattice is predicted to have better clumping resistance. Polyimide fibers (0.6 micron diameter) showing clumping behavior. [Majidi, Groff, Fearing 2004]. |

|

|

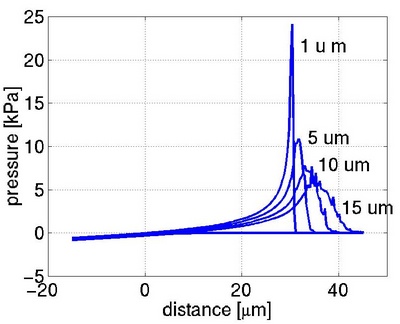

Effect of surface roughness on adhesion

strength (2003)

Surface roughness significantly reduces adhesion strength of fibrillar adhesives. A cantilever fiber model predicts a drop in adhesion by a factor of 5 when surface roughness increased from 1 to 15 um. [Campolo, Jones, Fearing IEEE Nano 2003] |

|

|

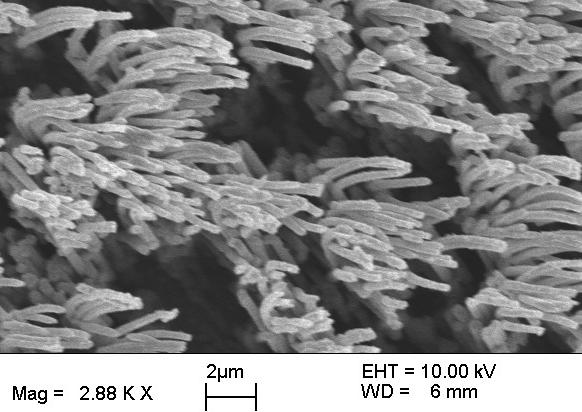

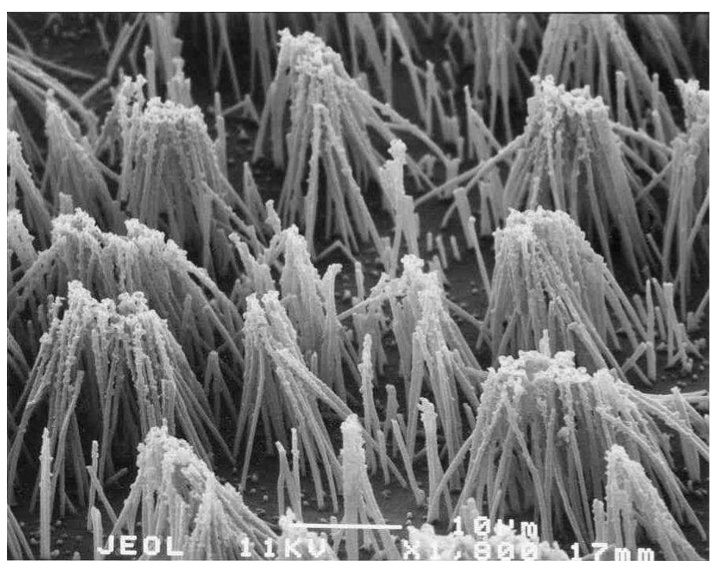

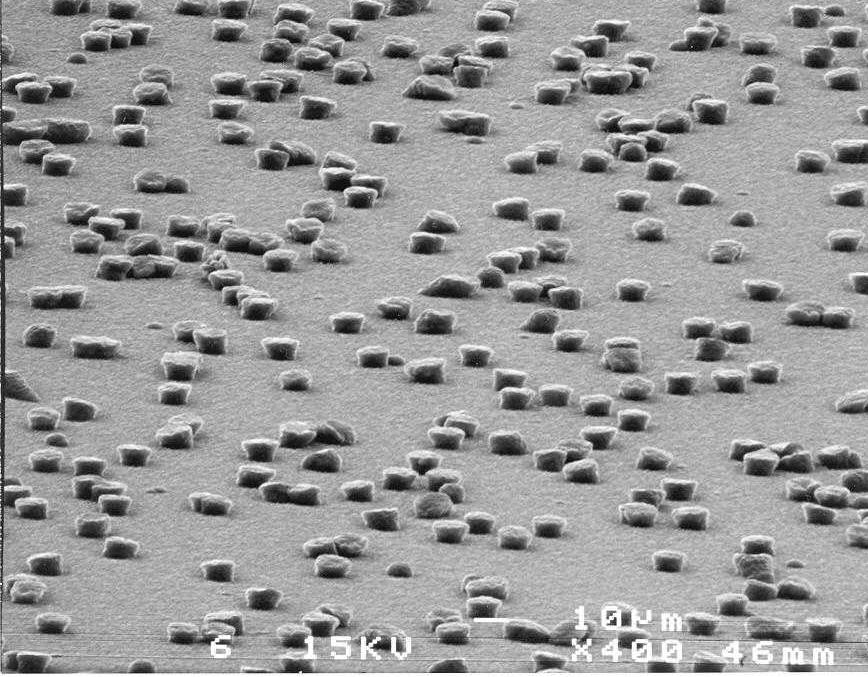

High

density nanofibers (2003)

Using a casting process in a template, polyurethane hairs 200 nm diameter and 60 micron long were fabricated. Due to clumping, adhesion force was limited. |

|

|

Synthetic spatula array (2002)

Synthetic spatula array from nano-indenting and casting. Approximately 200-300 nN adhesion force was measured per spatula. Total area of array was less than 100x100 sq. um. [Sitti and Fearing IEEE Nano 2002] |

|

|

Rubber micro stalk array (2002)

Array of silicone rubber stalks, each 6 um in diameter and 6 um height demonstrated 0.003 N/sq. cm. adhesion and 60 nN adhesion per stalk.[Sitti and Fearing IEEE Nano 2002] |

|

|

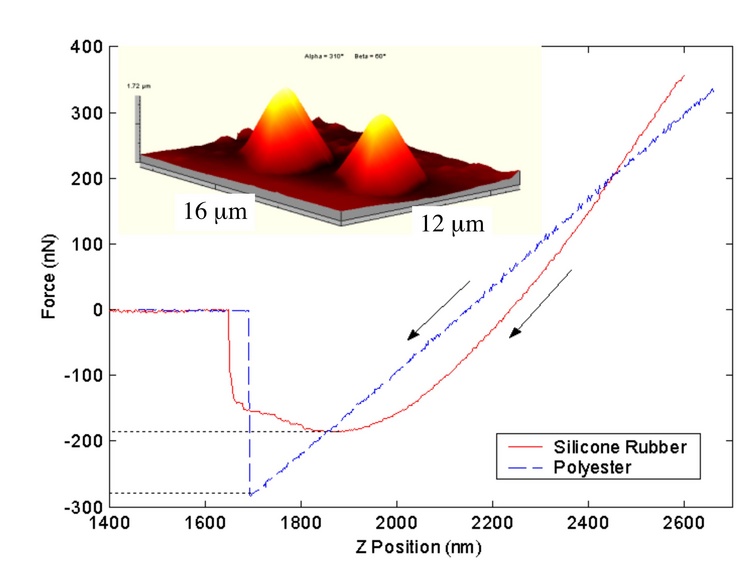

Synthetic spatula (2002)

Single spatula were constructed from silicone rubber (E ~ 0.5 MPa) and polyester (E ~ 1000 MPa) by using nano-indentation and casting. Using atomic force microscope, 290 nN pulloff force was measured from a single polyester spatula with tip radius of 350 nN, and 180 nN for silicone rubber. The similarity of pulloff forces supports the hypothesis of material independence for gecko adhesives. [Autumn et al. PNAS 2002] |

|

Sponsored by NSF ``Electrically-Controlled Nanofibrillar Surfaces for Cleaning and Adhesion'' (2009-2012)

Sponsored by NSF NIRT: ``Biologically Inspired Synthetic Gecko Adhesives'' (2003-2009).

NSF Disclaimer: ``This material is based upon work supported by the National Science Foundation under Grant No. EEC-0304730. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation (NSF).'' (previous sponsorship by DARPA (1999-2003) "Biomimetic Climbers" .)