| Gecko Adhesion Bibliography |

| Gecko Adhesion FAQ |

| History of Gecko Adhesion |

| Gecko Project |

Comparison of Fibrillar Adhesives (to glass)

(please email if you have updates to this data)NM= not measured

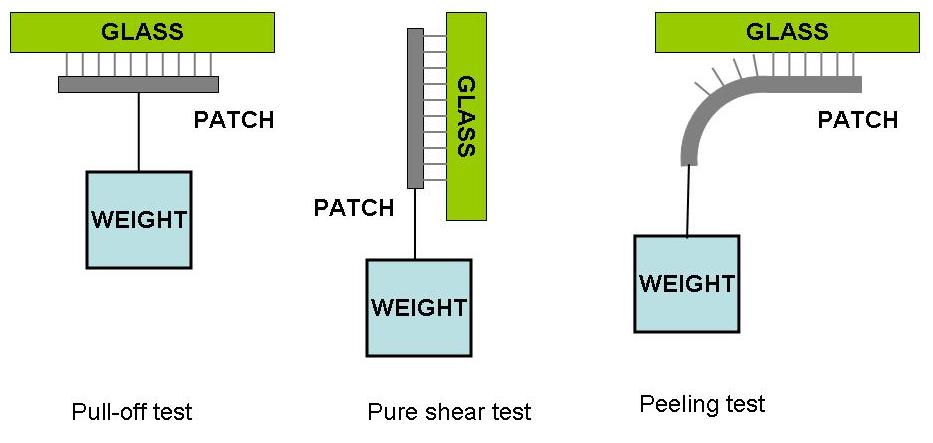

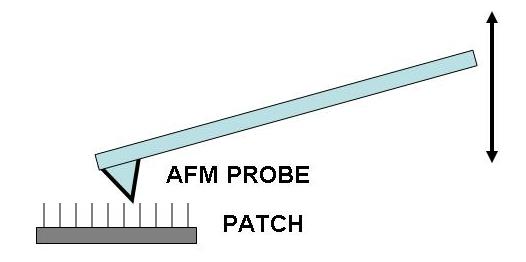

There has been much confusion in the press recently about the performance of various ``gecko-like'' products. One point of confusion is the comparison of nano-scale contacts, typically done with an atomic force microscope, to large patch areas. This is an apples-to-oranges comparison, as sophisticated hierarchical structures are used in the gecko to get adhesion over large areas, and any material in a nanoscopic contact will have a huge pressure. (Pressure is force divided by area, so as area goes to zero, the pressure tends to infinity.) Another source of confusion is the nature of what makes a sticky material. Soft rubbers and the soft materials used in pressure sensitive adhesives such as Scotch tape are naturally sticky because they can make conformal contacts with hard surfaces, as well as having appropriate viscosity properties. Soft sticky materials can make strong attachments, and by making fibers and stalks of soft material, patches with interesting adhesive properties can be made.

A second point is the attachment and detachment of a gecko adhesive. A gecko adhesive does not require being pressed into a surface- the fibers engage by being dragged parllel to the surface with minimal normal force. A gecko adhesive exhibits ``frictional adhesion'' where the fibers push off the surface if there is not a force parallel to the surface, giving automatic release.

| Comparison Tables: |

Hard polymer | Soft Polymer | Carbon Nanotube |

| Product |

normal stress (N/sq.cm.) (perp. pulloff) |

shear stress (N/sq.cm.) |

shear adhesion coefficient (1) |

frictional adhesion? (2) |

| gecko lamella (Lee et al. 2008) |

~0 |

54 |

>5 |

yes |

| HDPE GSA (Gillies et al. 2011) |

~0 |

30 |

>10 |

yes |

| polypropylene GSA (Lee et al. 2008) |

~0 |

1.6 |

~30 |

yes |

|

PUA inclined nanofibers (Jeong et al. 2009) |

~5 |

26 |

~70 |

yes (?) |

| polypropylene GSA angled fibers Lee et al. APL 2008 |

~0 |

4.5 |

~45 |

yes |

| carbon nanotubes (Qu et al. 2008) |

20 |

100 |

0.8 |

no |

| carbon nanotubes (Maeno and Nakayama APL 2009) |

? |

45 |

0.9 |

? |

Notes:

1) Shear adhesion coefficient is the ratio of pull-off shear stress to normal preload stress. A high adhesion coefficient means only a light contact will be needed to engage the adhesive.

2) Frictional adhesion is the key property where the normal pulloff force goes to zero when shear force is removed. In this way, the gecko can remove its foot with zero detachment force.

| Spherical Probe Tests |

|||||||

Load, drag, pull test |

Spherical indentation test Load then Pull off |

||||||

| Product

|

Material |

Modulus |

Probe Radius (R) |

Preload |

Load-Pull Normal Force and

F/R (N/m) |

Load-Drag-Pull Normal Force and

F/R (N/m) |

Adhesion Coefficient |

|---|---|---|---|---|---|---|---|

| Schubert et al JRS Interface 2008 |

polypropylene | 1 GPa |

5 cm |

2 mN |

< 0.05 mN (< 0.001 N/m) |

0.8 mN (0.016 N/m) |

0.4 |

| Northen and Turner Current Apl. Phys 2006 |

organorods |

~1 GPa |

0.3 cm |

12 mN |

0.45 mN (0.15 N/m) |

NM |

0.04 |

| Kim and Sitti APL 2006 |

polyurethane |

3 MPa |

0.3 cm |

22 mN |

65 mN (20 N/m) |

NM |

3 |

| Murphy et al. App. Mat. and Int. 2009 |

polyurethane |

3 MPa |

1.2 cm |

256 mN |

600 mN (50 N/m) |

NM |

2.3 |

| Murphy et al JAST 2007 |

polyurethane |

3 MPa |

0.3 cm |

4 mN |

8 mN (3 N/m) |

6 mN (2 N/m) |

1.5 |

| Greiner, del Campo, Arzt Langmuir 2007 |

silicone rubber |

2.6 MPa |

0.25 cm |

2 mN |

1.1 mN (0.5 N/m) |

NM |

0.5 |

| Greiner, Arzt, del Campo Adv. Materials 2009 |

silicone rubber |

1.9 MPa |

0.25 cm |

0.5 mN |

0.07 mN (0.03 N/m) |

NM |

0.14 |

| Nanoscopic Patches |

|||||||

| These

are measurements of very small numbers of contacts over a very

small area. The results at the nanoscale can not be directly

extrapolated to performance of macroscopic patches. In many cases an

atomic force microscope is used to make contact with one to several

fibers. Notes: (1) For natural gecko, we are assuming ``frictional adhesion'' mode, where a shear force is necessary for the pulloff force to be non-zero. (See Fig. 4 of Autumn et al Nature 2000). The shear and normal is estimated by assuming 100 to 1000 spatulae are in contact. Each spatula is assumed to be 200x200 nm. (2) Haeshin Lee, Bruce P. Lee & Phillip B. Messersmith, ``A reversible wet dry adhesive inspired by mussels and geckos, '' Nature,448, 338-341 (19 July 2007) |

|

||||||

| Product |

Material | Modulus |

Pull-off (nN) |

Shear (nN) |

Area sq. um. |

Normal stress MPa |

Shear stress MPa |

| (1) Natural Gecko, Autumn et al Nature 2000 |

beta keratin |

2 GPa |

20-200 |

35-350 nN |

0.04 |

0.5-5 |

0.9-9 |

| Sitti and Fearing IEEE Nano 2002 |

polyester |

0.85 GPa |

280 |

NM |

9 |

0.03 |

NM |

| Sitti and Fearing IEEE Nano 2002 |

PDMS |

0.5 MPa |

200 |

NM |

9 |

0.02 |

NM |

| Yurdumakan et al. Chemical Comm. 2005 |

carbon nanotube |

1000 GPa | 10 |

NM |

0.0006 |

16 |

NM |

| (natural gecko) Huber et al. PNAS 2005 |

beta keratin |

2 GPa |

20 |

NM |

0.04 |

0.5 |

NM |

| (2) Lee et al Nature, 2007 |

PDMS+ p(DMA-co-MEA) |

0.5 MPa? |

120 |

NM |

1 |

0.12 |

NM |