| |

|

|

|

|

|

|

|

|

|

|

|

|

Higher

Order Mechanisms:

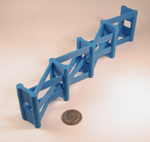

This transmission consists of a series connection

of cross-flexure joints, with additional interconnecting beam

flexures. When one cross-flexure joint is rotated, each of

the remaining joints exhibits rotation as well. As before,

the entire device is fabricated as one continuous piece. The

transmission also demonstrates another anticipated feature

of flexonics: modular construction. The flexonic transmission

is essentially a repeated pattern of cross-flexure joints.

Although this is only a one-dimensional pattern, we might

design other devices which contain a different modular unit

and employ two- or three-dimensional configurations.

Traditional motion generation mechanisms can be redesigned

within the flexonics design space. As an example, consider

the Peaucellier linkage pictured below. The function of the

linkage is to convert rotational motion into pure translation.

Under traditional design methods, the links are separate parts,

connected to each other via pivots at their ends. The flexonic

counterpart, however, can be one continuous piece, with traditional

pivots being replaced by small-length flexures (also called

notch flexures or "living hinges").

|

|

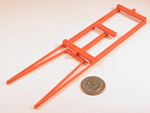

Mechanisms for specific functions like gripping are also relatively

easy to design. One such possibility is shown above. Instead

of discrete regions of flexion as used above in the Peaucellier

linkage, we implement distributed flexion along the gripper

"fingers". A simple translation of the center rigid

beam brings both fingers together.

back

|

| |

|

|

|

|

|

|