| |

|

|

|

|

|

|

|

|

|

|

|

|

Rotary

joints:

A traditional joint might employ some rolling

or sliding interaction between the two connected links in

the form of a hinge or bearing assembly. The flexonic counterpart

moves by deflection, where elastic energy storage provides

an increasing resistance to rotation. Other issues when designing

flexonic joints include range of motion, axis-drift, off-axis

stiffness, and stress concentrations. We have identified several

joint designs for possible inclusion within flexonic mechanisms.

Below is a simple thin-strip cross-flexure joint. The right

graphic depicts a cross-flexure joint in its rotated configuration.

|

|

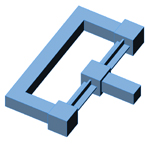

A rotary joint can also be designed by utilizing the twisting

degree of freedom of a thin strip. A realization of this joint

is proposed and analyzed in detail by Moon, et al [1]. The

joint utilizes perpendicular ribs along the flexure region

to constrain off-axis motion. The ribs are essentially the

intersection of two perpendicular thin strips. The axis of

rotation is along the center of the ribbed flexure.

back

[1] Moon, Y.-M., Trease, B. P., and

Kota, S., "Design of Large Displacement Compliant Joints",DETC2002/MECH-34207,

ASME/DETC 27th Biennial Mechanisms and Robotics Conference,

Montreal, CANADA, Sep.29~Oct.3, 2002

|

| |

|

|

|

|

|

|