Smart Gecko Tape

First gecko adhesive which is |

|

|

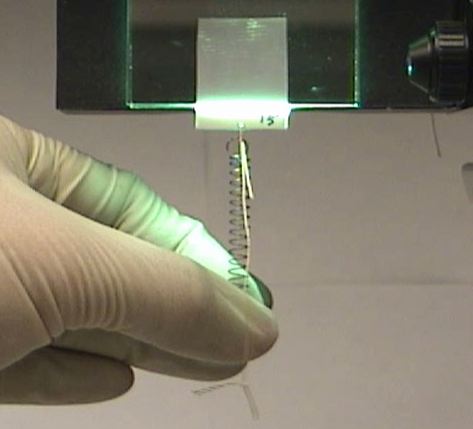

Movie of gecko tape.

Contact area (bright region on top) increases with load, and when patch starts to slide. [Movie (wmv)] [Movie (mov)] |

POC: Prof. Ronald Fearing

Dept. of Electrical Engineering

University of California, Berkeley

(510) 642-9193 ronf@eecs.berkeley.edu

|

|

Tokay foot image courtesy of Prof. Kellar Autumn, Lewis and Clark College. Contact autumn@lclark.edu for permission. [Image] |

|

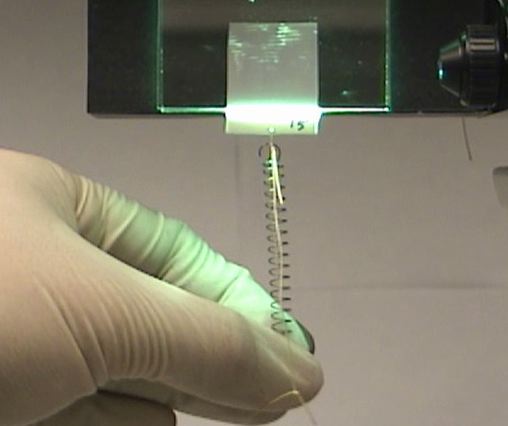

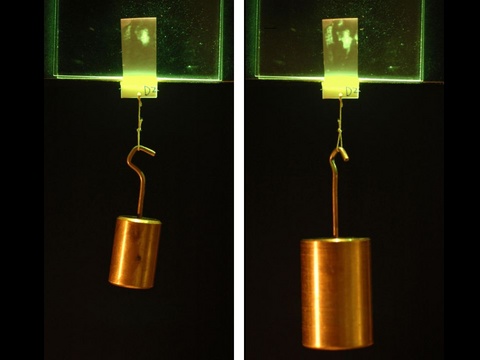

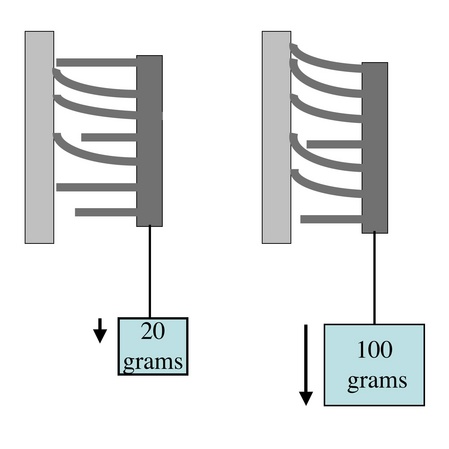

| Gecko-inspired

adhesive supporting weight. Increasing weight increases

contact area.

Contact area is bright area near top of patch. Adhesive is ``smart'' in

that greater load causes more microfibers to engage, increasing

adhesion strength. Decreasing load allows fibers to disconnect,

making release easy.

Print-quality images available for download |

Controllable adhesion is key for climbing

While much previous research has focussed on making stronger gecko-inspired adhesives, easy grip and release is also required for climbing. The reported gecko-inspired synthetic adhesive (GSA) is the first hard polymer microfiber adhesive which can attach without requiring high pressure. The adhesive releases easily when the sliding force is removed. While the present microfiber array works on smooth surfaces, future versions could be useful for medical equipment, sporting goods, or climbing robots where a controllable and reusable adhesive is needed.The gecko-inspired synthetic adhesive is described in a

2 part paper

appearing online in the Journal

of the Royal Society Interface (Jan. 23, 2008).

[2] B. Schubert, J. Lee, C. Majidi, and R. Fearing, ``Sliding induced adhesion of stiff polymer microfiber arrays: 2. Microscale behaviour,'' Journal of the Royal Society, Interface (10.1098/rsif.2007.1309)

POC: Ronald Fearing (510) 642-9193, ronf@eecs.berkeley.edu

How the switchable gecko adhesive works

Similar to the natural gecko setal array, our microfiber array is a shear-controlled smart adhesive. Contact area increases with increased shear load and virtually disappears when shear load is removed, allowing for controlled attachment and detachment. This is a critical innovation for clean release, and reuse, and has not been demonstrated before with a hard microfiber array. Microfiber array adhesion is reworkable in the sense that contact is maintained as the sample slides on a surface. Reworkability is a critical property for gecko-inspired climbing, where slip can increase the shear force, and the animal or robot can recover from slip without falling during climbing. |

|

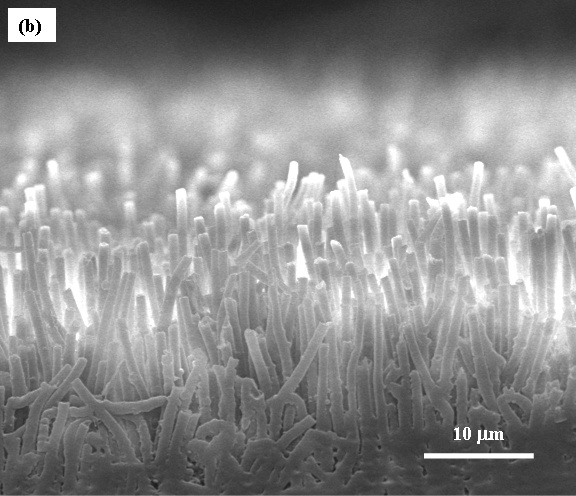

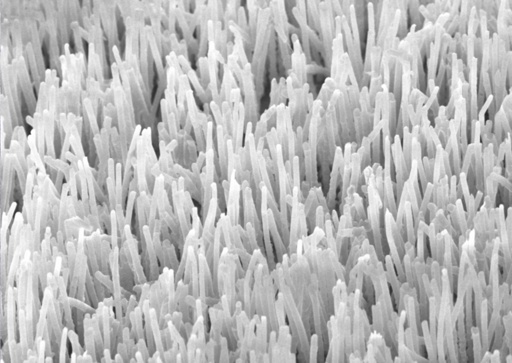

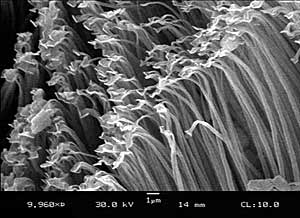

| Side view of polypropylene microfibers. Each fiber is 15-20 micrometer long, and 0.6 micrometer in diameter. | Conceptual drawing showing how more microfibers contact glass when load increases. |

A pair of scanning electron micrographs show similarities between synthetic polymer fibers created by UC Berkeley researchers (above) and the setae from an Anolis lizard. (Photo below of Kellar Autumn, Lewis & Clark College)  |

Comparison to natural gecko

Prof. Kellar Autumn of Lewis and Clark College (Oregon)

has identified 7

key properties for gecko adhesives. The polypropylene

gecko adhesive is the first synthetic gecko adhesive to demonstrate 5

of these 7 properties in a single material:

1. Directional attachment

The microfibers do not attach by being pressed into the surface, and

instead require a sliding motion parallel to the surface for the fibers

to bend and attach.2. High pulloff force to preload ratio

A preload of less than 0.1 Newton is sufficient to

engage the fibers, and after the preload is removed, the patch can

sustain a shear load of 4 Newtons.

3. Low detachment force

4. Anti-self-matting

The polypropylene fibers do not stick to one another, and do not clump even with 100s of loading/unloading cycles.5. Non-sticky default state

The polymer used in the synthetic adhesive,

polypropylene, is almost as hard as the keratin used by natural gecko,

and the surface of the patch is non-sticky.

Gecko adhesive properties 6: Topography independence

(sticking to rough surfaces), and 7: Self-cleaning are part of

current research efforts.

This research is supported by the National Science Foundation, under Nanotechnology Interdisciplinary Research (NIRT) Program: ``Biologically Inspired Synthetic Gecko Adhesives''.

NSF Disclaimer:

``This material is based upon work supported by the National Science

Foundation

under Grant No. EEC-0304730. Any opinions, findings and conclusions or

recommendations expressed in this material are those of the author(s)

and do not necessarily reflect the views of the National Science

Foundation

(NSF).''

Links

UC Berkeley Press Release

Biologically Inspired Synthetic Gecko Adhesives Project

Previous work on high friction gecko inspired materials (2006).

Background information on gecko adhesion

Comparison tables for gecko-inspired synthetic adhesives

Bibliography of papers on gecko adhesion

Background information on gecko adhesion

Geckos' five-toed feet are each covered with millions of tiny hairs called setae, and like split ends, each seta branches out into billions of nanoscale spatulae. In 2002, a team of UC Berkeley engineers including Ronald Fearing and Metin Sitti (now at CMU), UC Berkeley biologist Robert Full, Lewis and Clark College biologist Kellar Autumn, UC Santa Barbara engineer Jacob Israelachvili, and Stanford University engineer Thomas Kenny, found that the network of gecko hairs forms intermolecular bonds with the surface by means of van der Waals forces. (Link to discussion of 2002 PNAS paper.) The same research team synthesized gecko hair tips that stick, providing the first direct experimental verification of a van der Waals mechanism for gecko foot-hair adhesion. Those forces only come into play when surfaces get intimately close. When millions of gecko hairs make contact, they collectively create a powerful bond that is a thousand times stronger than the force geckos need to hang onto a wall.Even more impressive is the gecko's ability to attach and detach from the surface as many as 15 times per second. The lizards are able to adhere strongly to a surface with just the slightest step, something that has only now been demonstrated with a gecko-inspired synthetic adhesive.

|

img src= http://www.lclark.edu/%7eautumn/dept/Images_files/IMG_1210-angry1.jpg

title="" alt="Angry Gecko" style="width: 310px; height: 231px;"> |

img src= http://www.lclark.edu/%7eautumn/dept/Images_files/Macro-Nano.jpg

title="" alt="gecko hierarchy" style="width: 360px; height: 226px;"> |

| Gecko image courtesy of Prof. Kellar Autumn, Lewis and Clark College. Contact autumn@lclark.edu for permission. | Gecko adhesion from

toes to nanostructures. Image courtesy of Prof. Kellar Autumn, Lewis and Clark College. Contact autumn@lclark.edu for permission. |

Paper Summary

A new gecko-inspired adhesive using hard plastic microfibers is ``switched on'' by sliding. Like a gecko's toe, the synthetic is not sticky when pressed into a surface, but the microfibers adhere when bent over by sliding. The adhesive force increases with sliding distance, which could provide an automatic braking effect. Surprisingly, the gecko-inspired adhesive gets stronger the more it is used. A 2 centimeter square patch can support a 400 gram load, but like a gecko toe, the adhesive easily detaches. In contact regions, the synthetic patch achieves one sixth as much sliding adhesion as the real gecko on smooth glass. The fibers, packed 42 million per square centimeter, are 20 micrometers long (one fifth the thickness of a sheet of paper) and 0.6 micrometers in diameter (one hundredth the diameter of a human hair). Each fiber can support a load of 200 nanoNewtons when it bends into contact with a surface.In testing with a spherical probe, the gecko-inspired adhesive is ``switched on'' by sliding a distance of only 20 micrometres. Without sliding, no adhesive forces are measured. After sliding, a pulloff adhesive force can be measured, but only while maintaining the sliding (shear) force. This ``frictional adhesion'' is a novel property used by geckos to easily detach by simply reducing the applied shear force. As with real gecko hairs, the microfibers are made from a hard polymer (polypropylene), which is not tacky, and can resist wear.