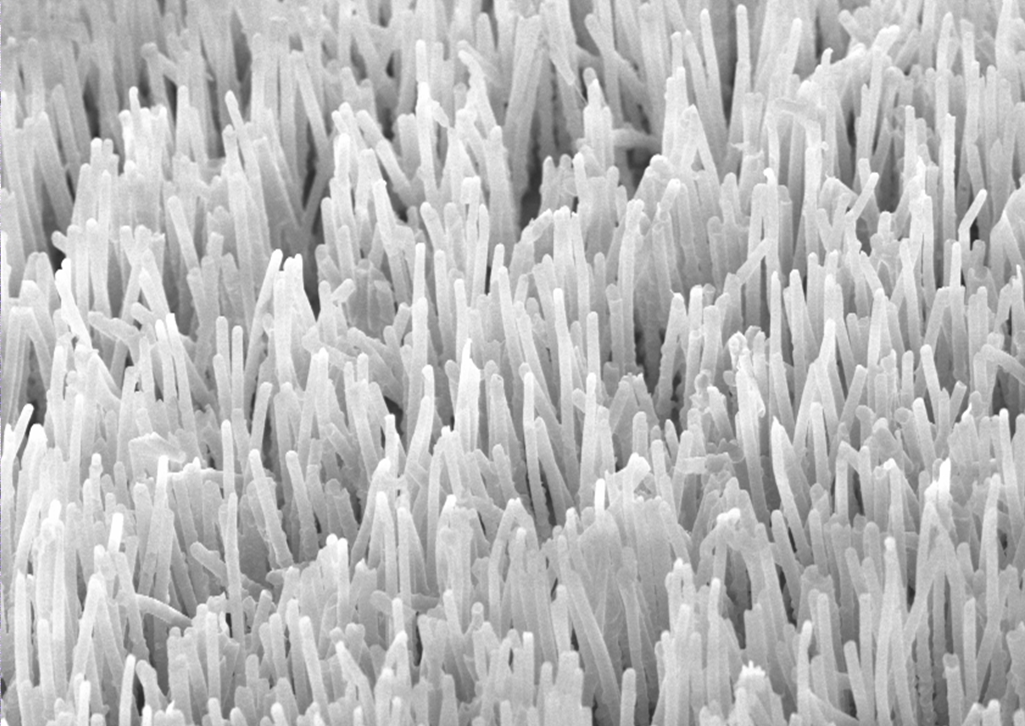

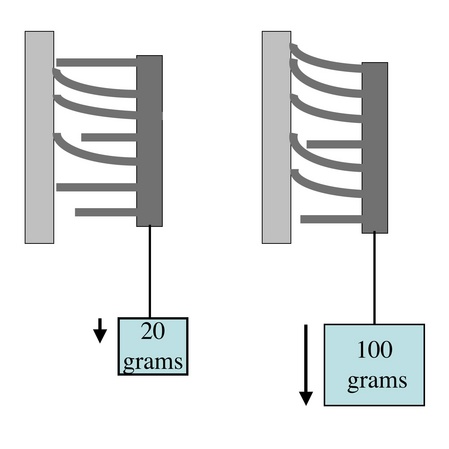

Polypropylene microfiber array

[image]

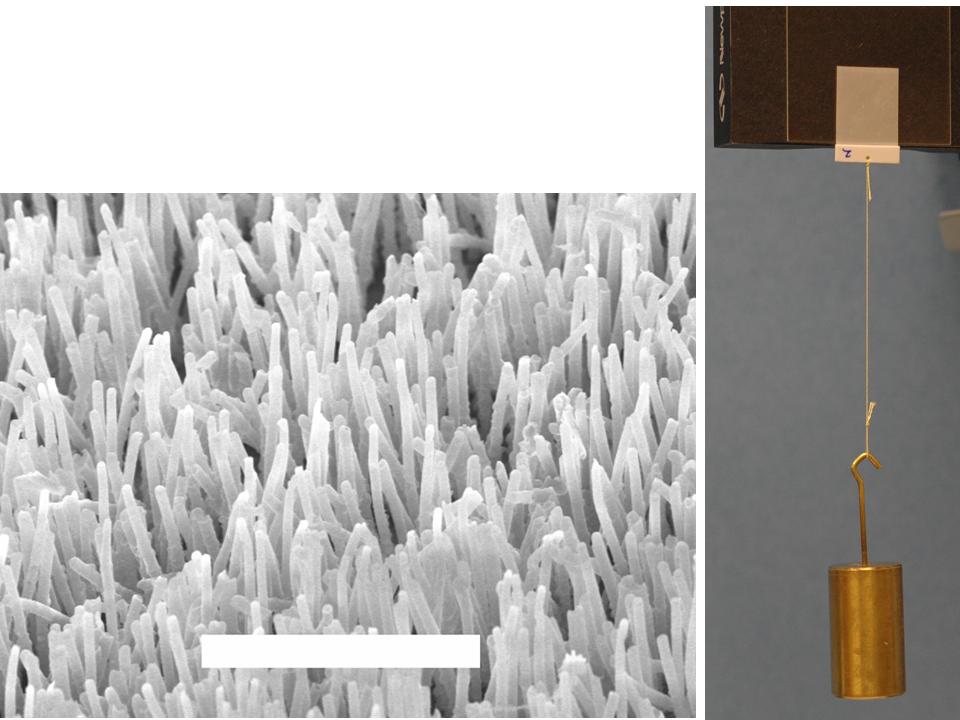

Electron microscope image of fiber array and patch holding weight

[image]

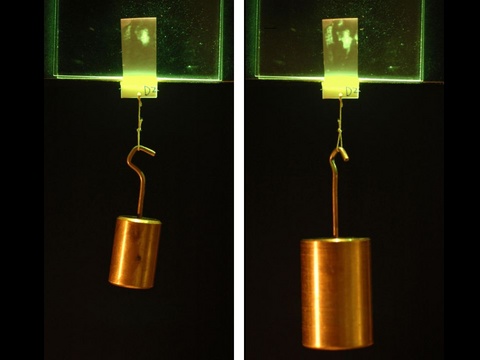

Patch supporting weight. Increasing weight increases contact area. Contact area is bright area near top of patch.

[Image]

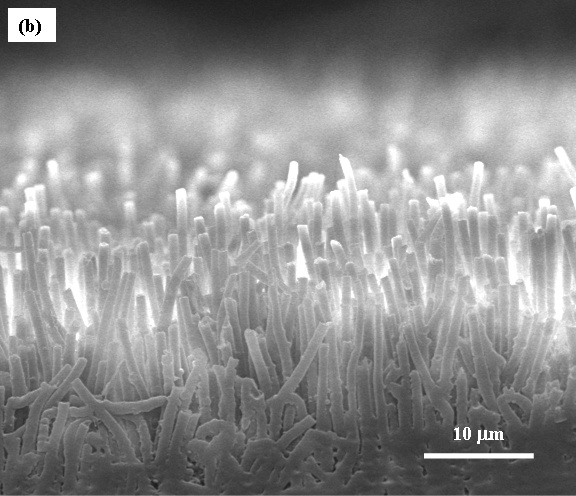

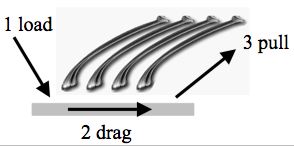

Side view of polypropylene microfiber array.

[Image]

Polypropylene synthetic gecko adhesive supporting 400 gram weight.

[Image]

Conceptual drawing showing how more microfibers contact glass when load increases.

[Image]

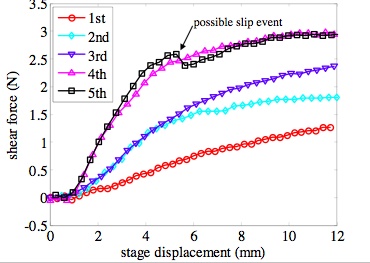

Fiber array performance improves by factor of 3 after 5 uses.

[Image]

Increase of shear adhesion with sliding distance of natural gecko.

[Image]

Increase of shear adhesion with sliding distance of synthetic gecko adhesive.

[Image]

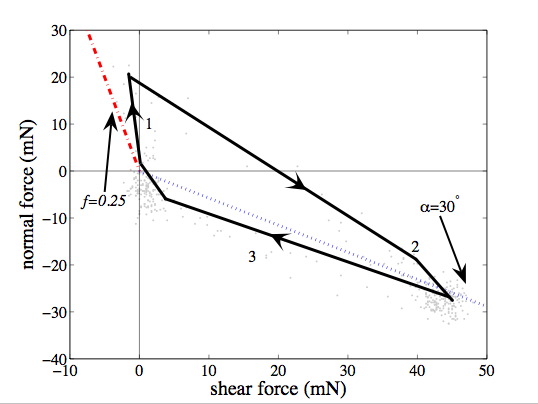

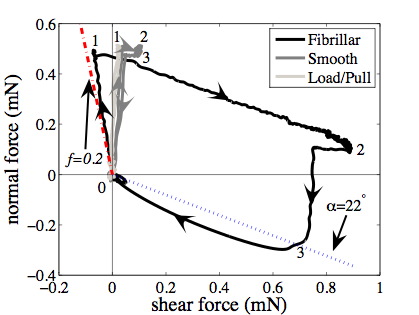

Testing path for natural gecko setal array.

[Image]

Frictional adhesion for natural gecko setal array. Normal force goes to zero when shear force is removed.

[Image]

Frictional adhesion for synthetic polypropylene microfiber array. Normal force goes to zero when shear force is removed.

[Image]