cs 298-4

cs 298-4

"Seminar on Self-Assembly"

General Home Page and Index, Fall 2005

1. Catalog Entry and Schedule

EECS 298: Seminar on Self-Assembly

-

FULL COURSE TITLE: Group Study on Self-Assembly

-

INSTRUCTORS: Ron Fearing, Kris Pister, Carlo

H. Séquin

-

COURSE NUMBER: CS 298-04

-

COURSE CONTROL NUMBER: 26832

-

UNIT VALUE: 1

-

SEMESTER: Fall 2005

-

CLASS TIME: Mondays, 4:10 - 5:30pm, 380 Soda Hall;

-

OFFICE HOURS: in the offices of the instructors, as per their posted hours.

PREREQUISITES:

2. Latest Course Description

Group Study on Systems Suitable for Unsupervised (Self-)Assembly

Ron Fearing, Kris Pister, Carlo

H. Séquin

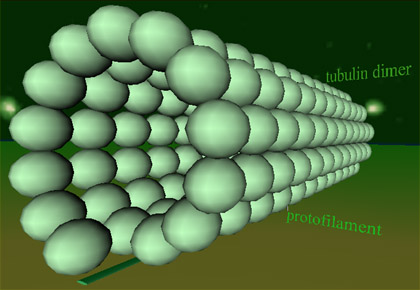

In this seminar series we will explore structures and algorithms for unsupervised self-assembly in nature

as well as in engineering, from the molecular level to large space structures such as radio telescopes.

Through a combination of selected readings and discussion, and through presentations by various experts in this field,

we plan to discover common paradigms at the geometric, kinematic, and algorithmic levels and gain an understanding

how such paradigms can be carried from nature to biomechanical and engineering applications.

Ideally, the result would be one or more white papers for further research,

which may then form the basis for future proposals for funding in this area.

TEXTBOOKS:

- NONE -- We will use the Web.

3. Initial Questions -- Some Food for Thought:

- What are viable "1D-", "2D-", "3D-" components and their connectors suitable for (self-)assembly ?

- i.e., find generic "LEGO" blocks used in nature and usable in engineering.

- What are possible realizations of "snap-together" connections ?

- Barbed hooks

- Expandable "wall anchors"

- Contact cement

- Polished surfaces (in vacuum) held together by Van der Waals adhesion

- Gecko feet

- What kind of grammars can describe all possible structures

that can be formed with a finite set of different parts and connectors ?

- What are the domains where unsupervised (self-)assembly has the highest potential payoff ?

- For systems built from too many components to be practical for piece-by-piece, one-at-a-time assembly.

- Systems in areas hostile to human assemblers: space, deep-sea, inside volcanos ...

- Domains where human "fingers" cannot easily reach to: MEMS, NEMS, BIO ...

- How much intelligence should be involved in assembling such structures?

- None -- i.e., random motion, as in polymerization ...

- A lot, as in smart mobile robots looking for individually

labeled parts (perhaps with RFID tags) and move them into their proper

places ...

- Something in-between that just looks for the right kind of connector ...

- Where should such intelligence be located ?

- Centralized? (Probably not!)

- On some independent agents ?

- Built into the parts to be assembled ?

- How can production and assembly of parts be effectively combined ?

- e.g., visualize an injection-mold production unit that spits

out mostly 2D parts that connect along their edges; but rather than

letting those parts fall into a bin or drift away, they are hooked up

in an orderly manner (e.g., a 1D ribbon, or a 2D sheet of finite width)

right after production.

- If such parts have the right shape, they can form folding

structures that might be flat in the original assembly state, but can

then be nugged into another energy minimum where they form a predefined

useful 3D structure.

- What CAD tools are required to design suitable parts of the

type described above that can automatically expand/fold into a

desirable 3D shape?

- BRING YOUR OWN QUESTIONS TO THIS SEMINAR.

Last update of this page: 2005/7/22

Page Editor: Carlo H. Séquin

cs 298-4

cs 298-4