How to Make a Flexible Curved Tactile Display

Disclaimer: The process and files are provided AS IS and

unsupported. There is no guarantee that this process will work for you.

Many hours have been devoted to developing this process and design, so

there is a lot of experience involved in making these tactile displays.

Notes

This webpage is basically a reproduction of Appendix B of my

dissertation, available for download on the sidebar. The dissertation

has descriptions of the following:

Electronics and pneumatics used to drive the tactile displays

The tactile sensors used to provide data to the tactile displays

The psychophysics testing and results

We started developing and refining this process no later than February 2000.

Previously, we made a flat tactile display that is discussed in an

ICRA

2000 paper.

Full resolution pictures can be seen by clicking on any picture.

Use of pictures for anything other than personal use by permission only.

Materials and Equipment

- Computer with SolidWorks

- Dow Corning HS II Silicone Rubber Base

- Dow Corning HS II Colored (pink) Catalyst, 10:1

- 3D Systems

ThermoJet

- 2mm Outer Diameter Silicone Tubing (See

New Age Industries

part number 2810458)

- Plastic cup, Scale, and Vacuum Chamber

- Miscellaneous clamps, weights, flat plexiglass pieces, and X-Acto knife

The whole fabrication process takes approximately 2 days, as it takes 24

hours for the HS II to cure.

Mold Preparation

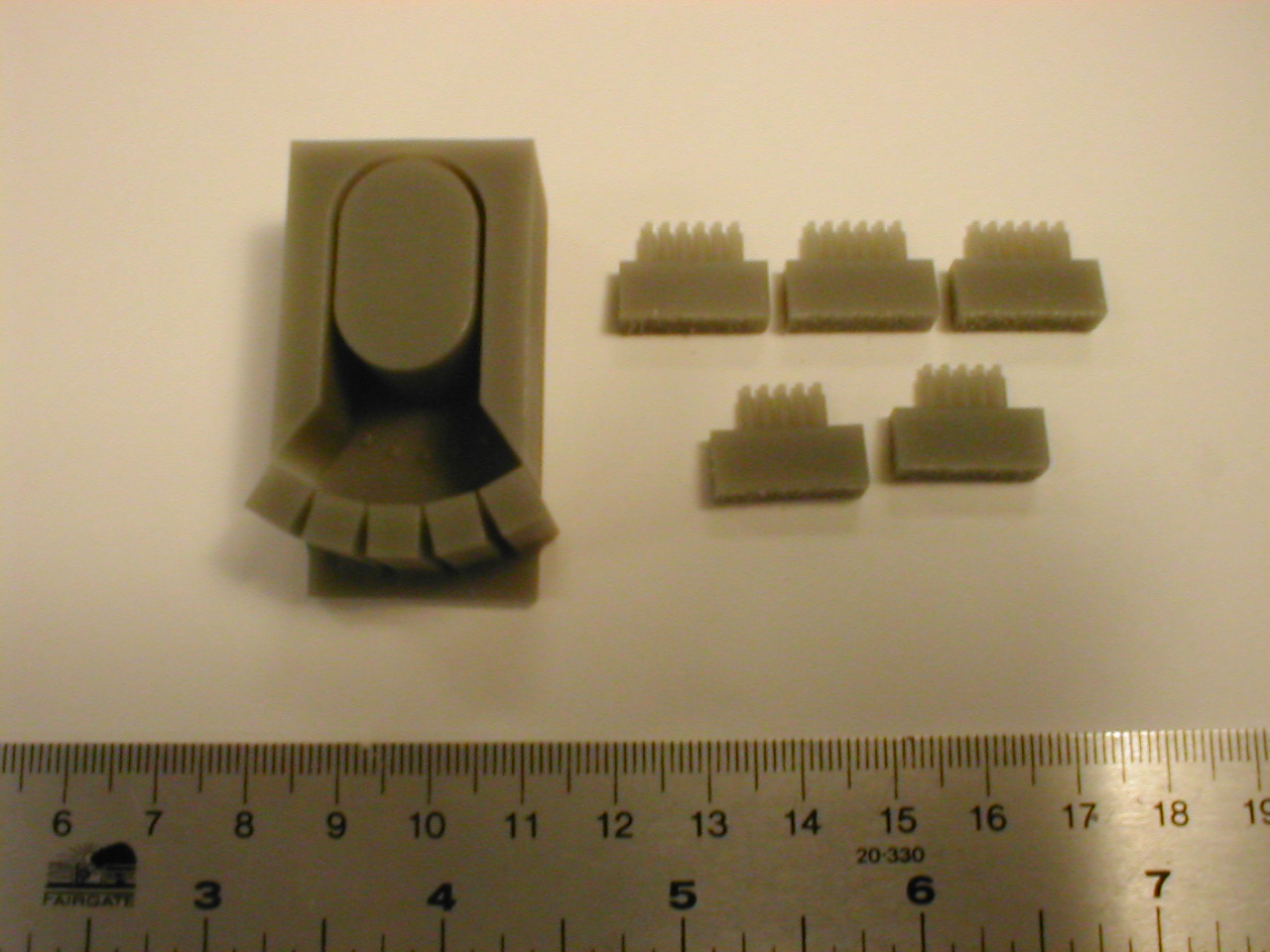

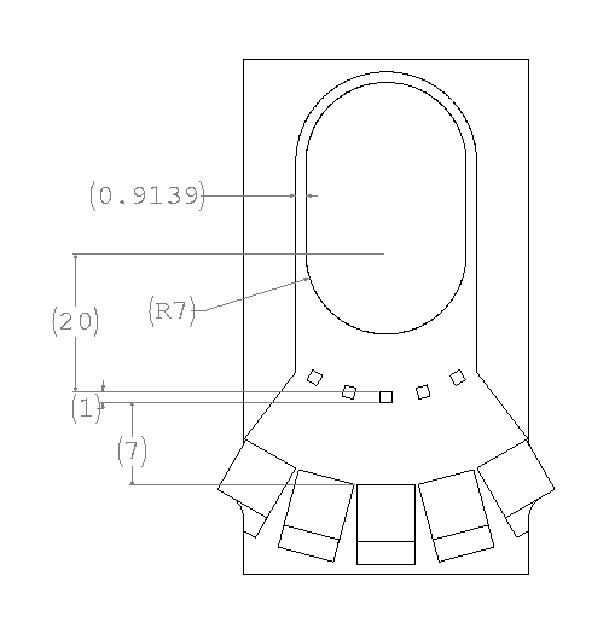

Using the Solidworks files available for download on the sidebar, we use the

ThermoJet to create the sacrificial mold. Have Solidworks save the designs

as STL files that the ThermoJet can take as input.

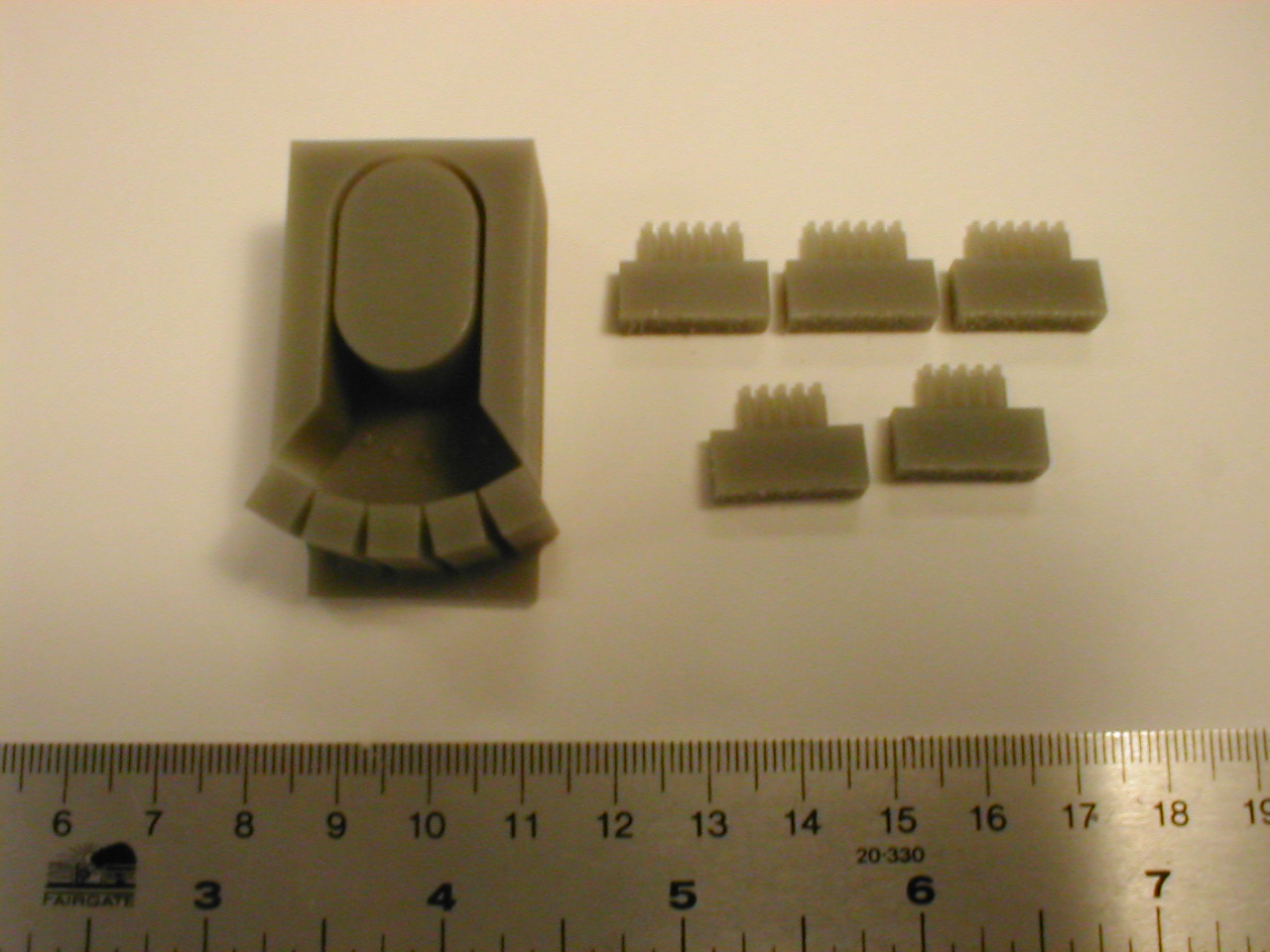

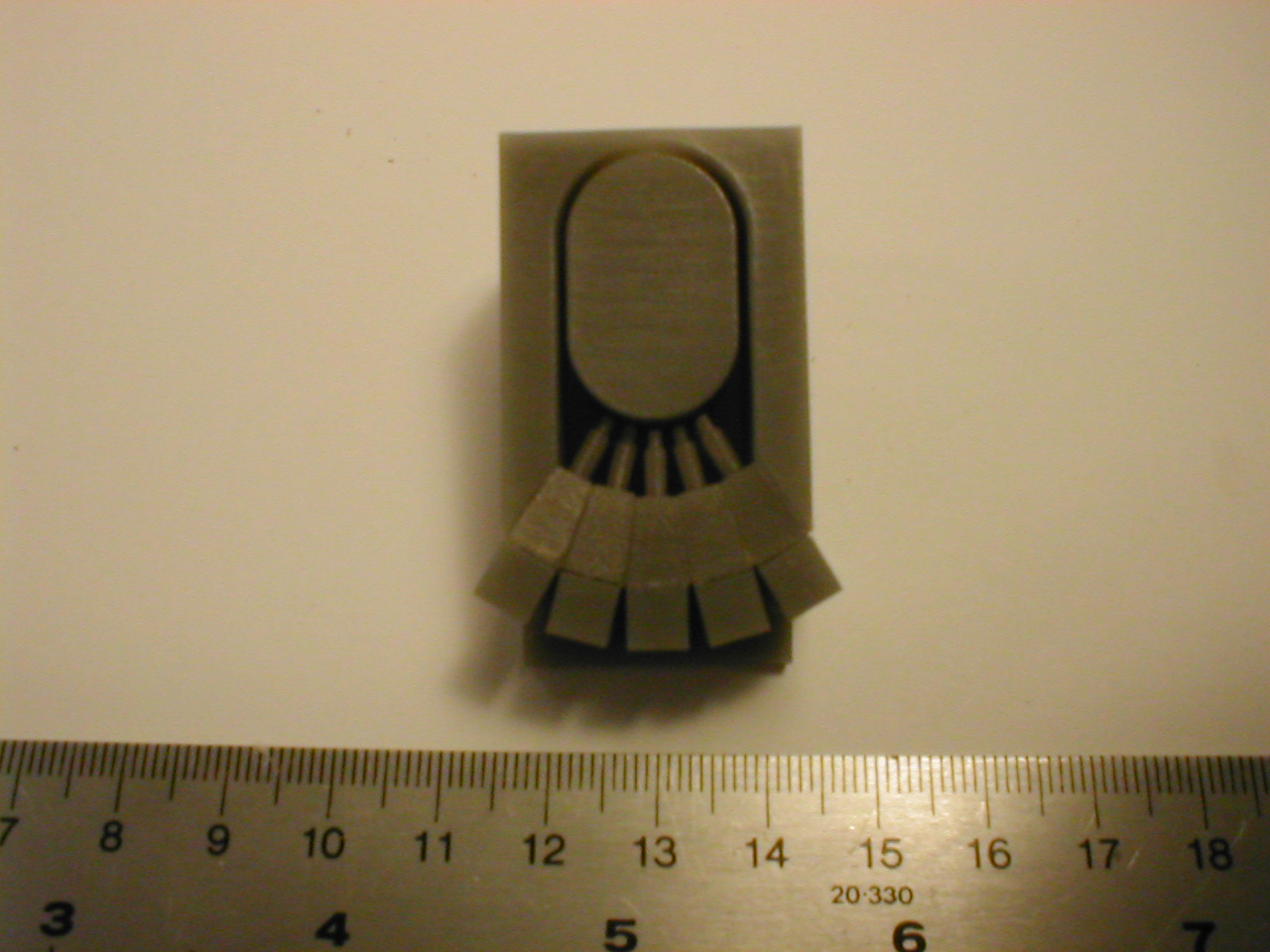

Carefully slide the pin pieces into the base. It will be a really

snug fit. The mold is shown below:

This mold makes a tactile display with 28 elements spaced 2mm apart and

hexagonally packed (6-5-6-5-6).

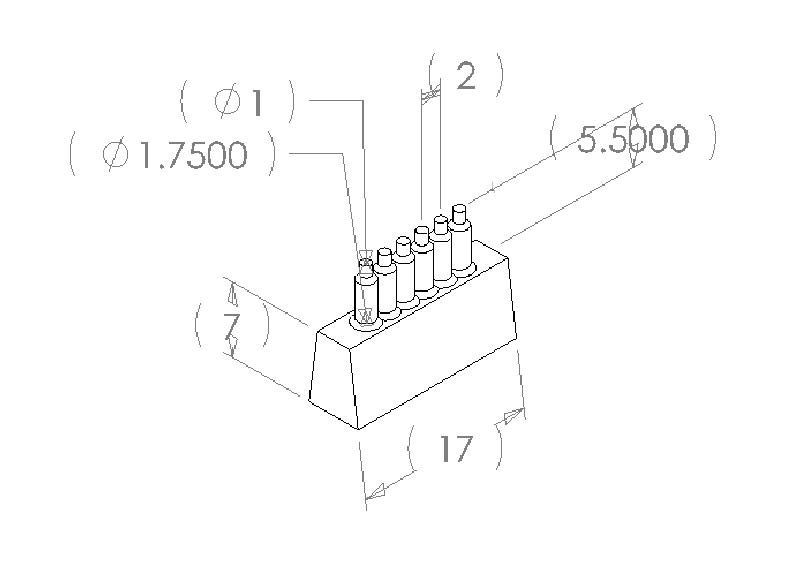

The finger interface has a 14 mm diameter. The pin height

determines the thickness of the rubber layer between the air chambers

and finger. In our case, we use a 5.5 mm pin height to achieve a 0.5 mm

membrane thickness.

The pins have a 1 mm diameter top section and a 1.75 mm bottom section.

The bottom section allows for the 2 mm silicone tubing to be inserted

securely into the display. The 5 rows were spaced at 15 degree intervals,

leading to a 2 mm spacing along the circumference of the finger/display

interface. Line drawings with dimensions are shown here:

Note: On the base, the 20mm mark should be from the center of the R7 to the

aligning block and not as shown... 20mm = 7mm radius + 0.5mm membrane +

5.5mm pin + 7mm pinbase.

First Molding

Measure out Dow Corning HS II base and pink catalyst in a 10:1 ratio. Mash

the

catalyst into the base. Vacuum the mixture until there are no more big air

bubbles coming from the mixture. Pour HS II into the mold until it

overflows

over the sides. Vacuum the mold until there are no more medium air bubbles

coming from the mold. This vacuum step might take 20 minutes. Remove mold

from the vacuum chamber and place a plexiglass plate on top of the mold.

Place weights on top of the plexiglass and let the HS II cure for 24

hours.

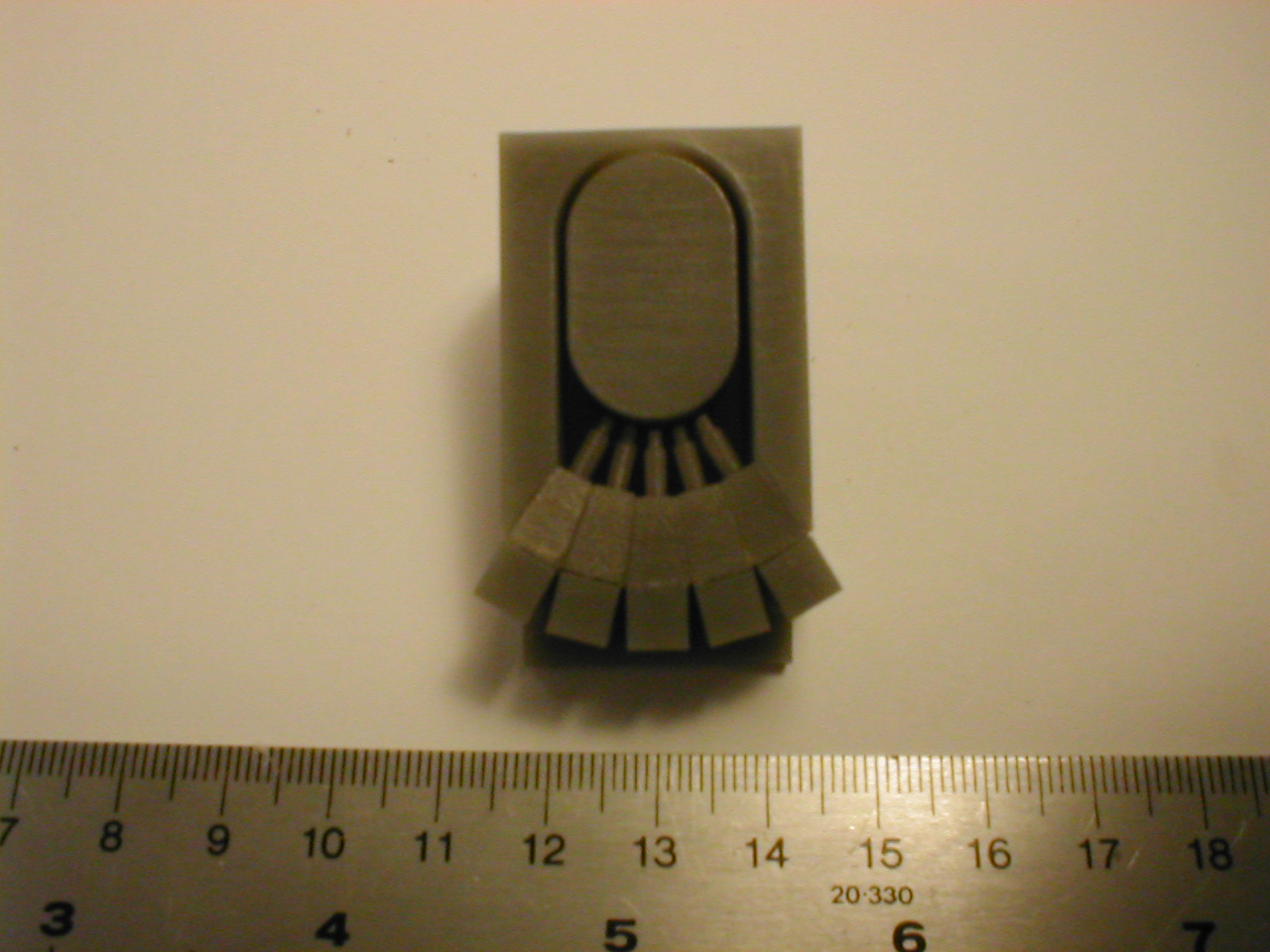

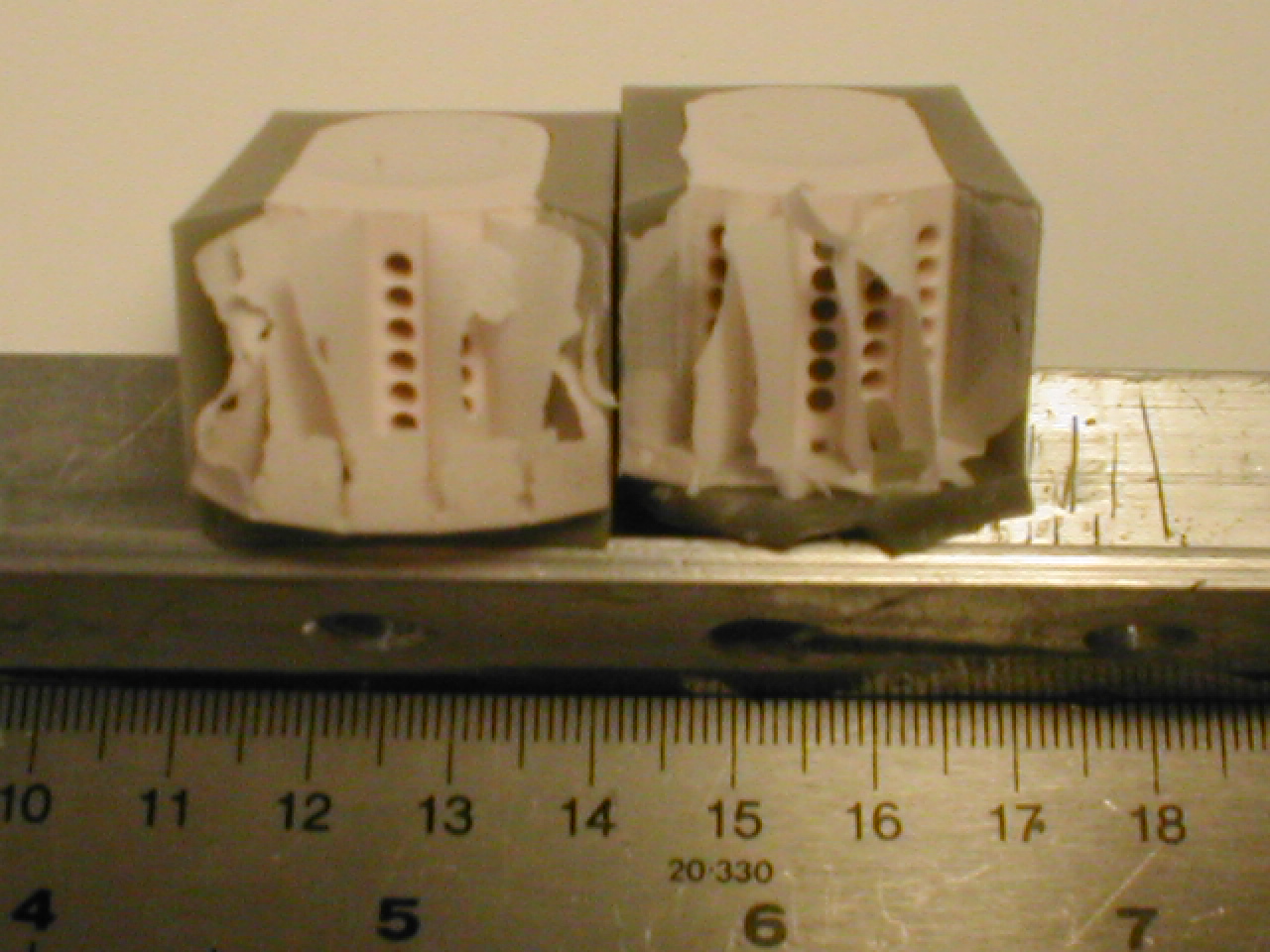

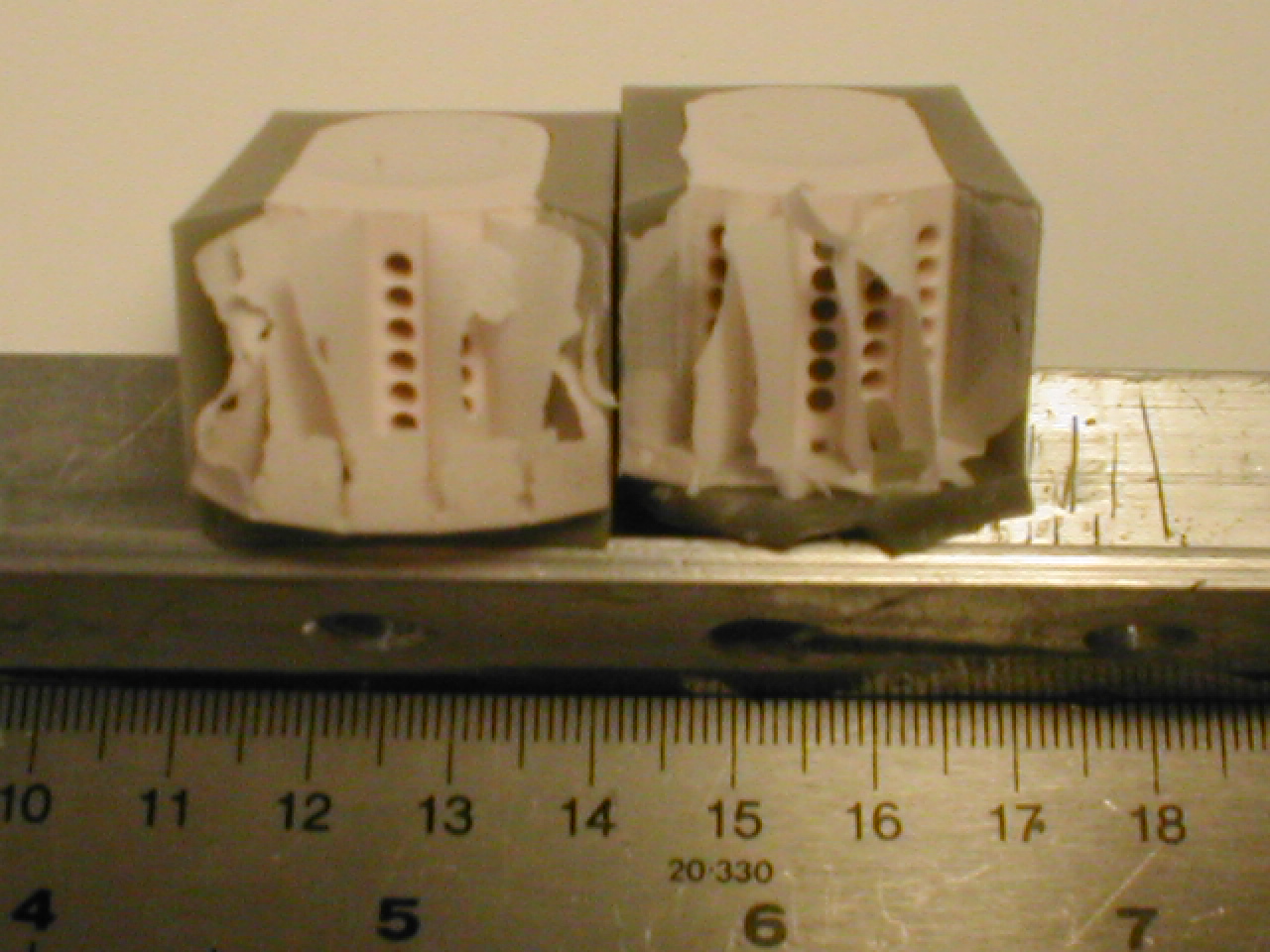

Remove weights and plexiglass plate. Use an X-Acto knife to remove

excess rubber until you get something resembling this picture:

Carefully break off the five support beams behind the pin piece molds.

Slide out the 5 pin pieces. Remove broken pin piece structures left

inside the mold with tweezers. Trim excess rubber with an X-Acto knife.

Tube Insertion

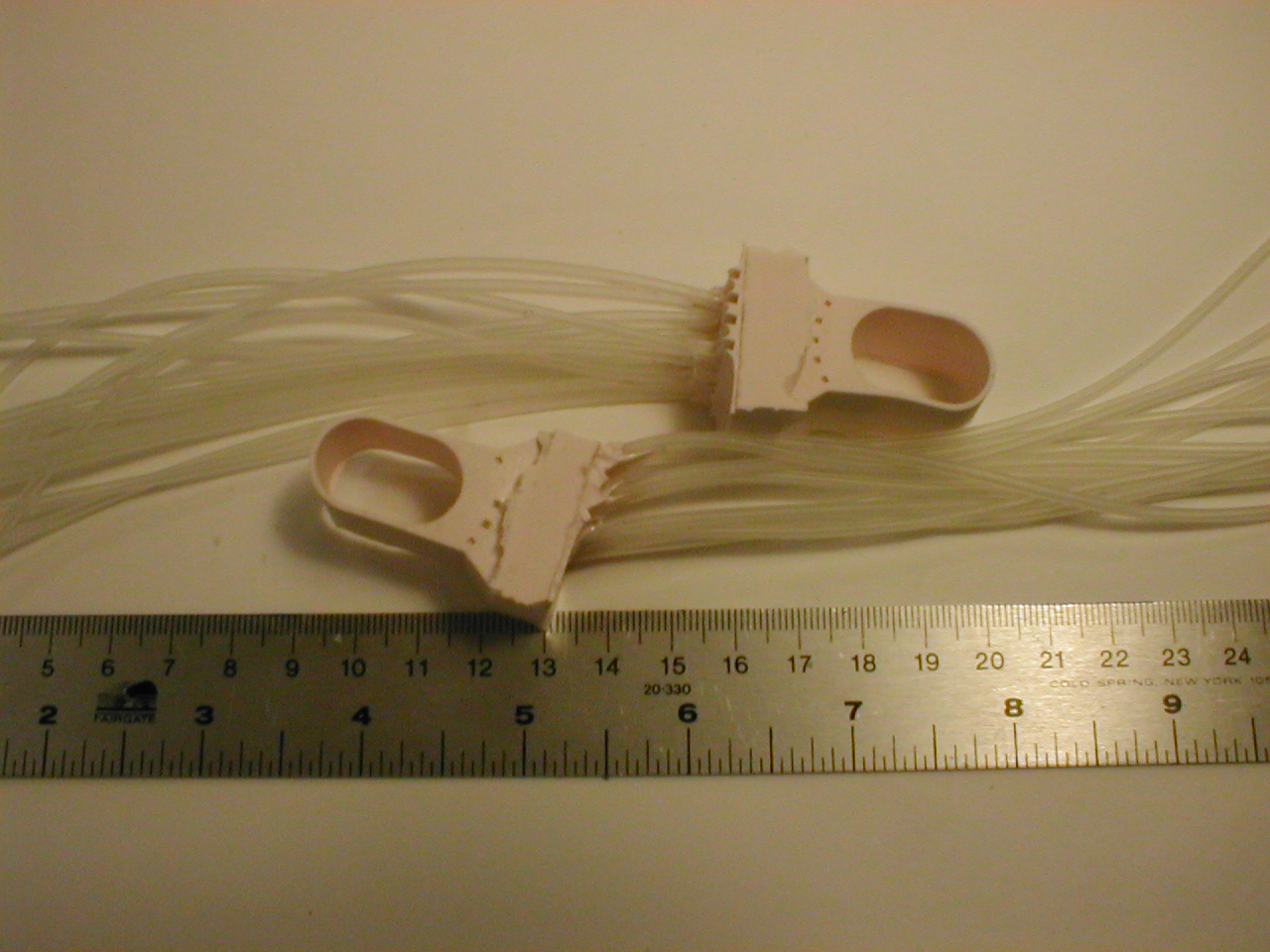

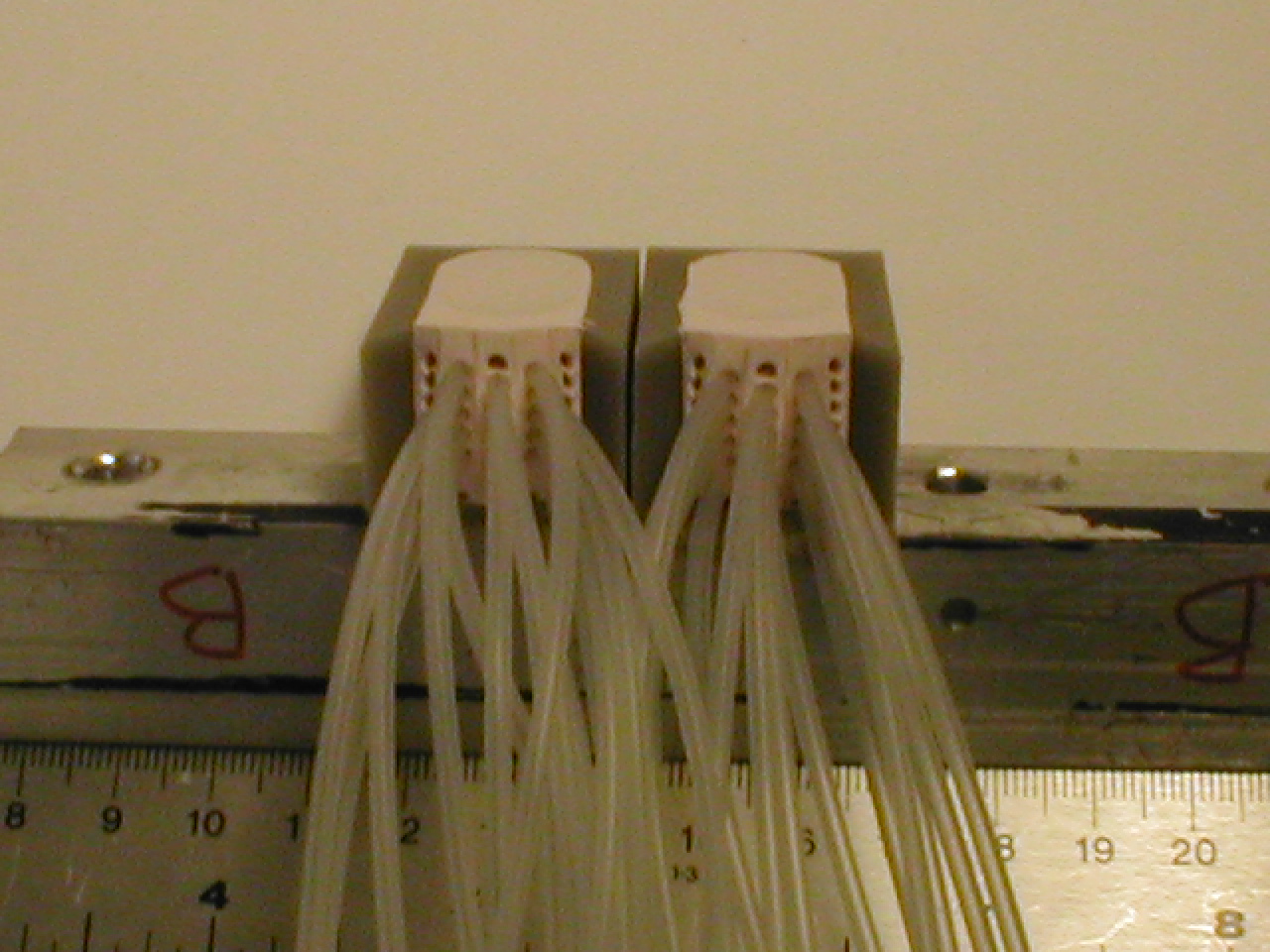

Determine how many elements you want to have in your tactile display.

Cut silicone tubes to the desired length. Push the tubes into the mold.

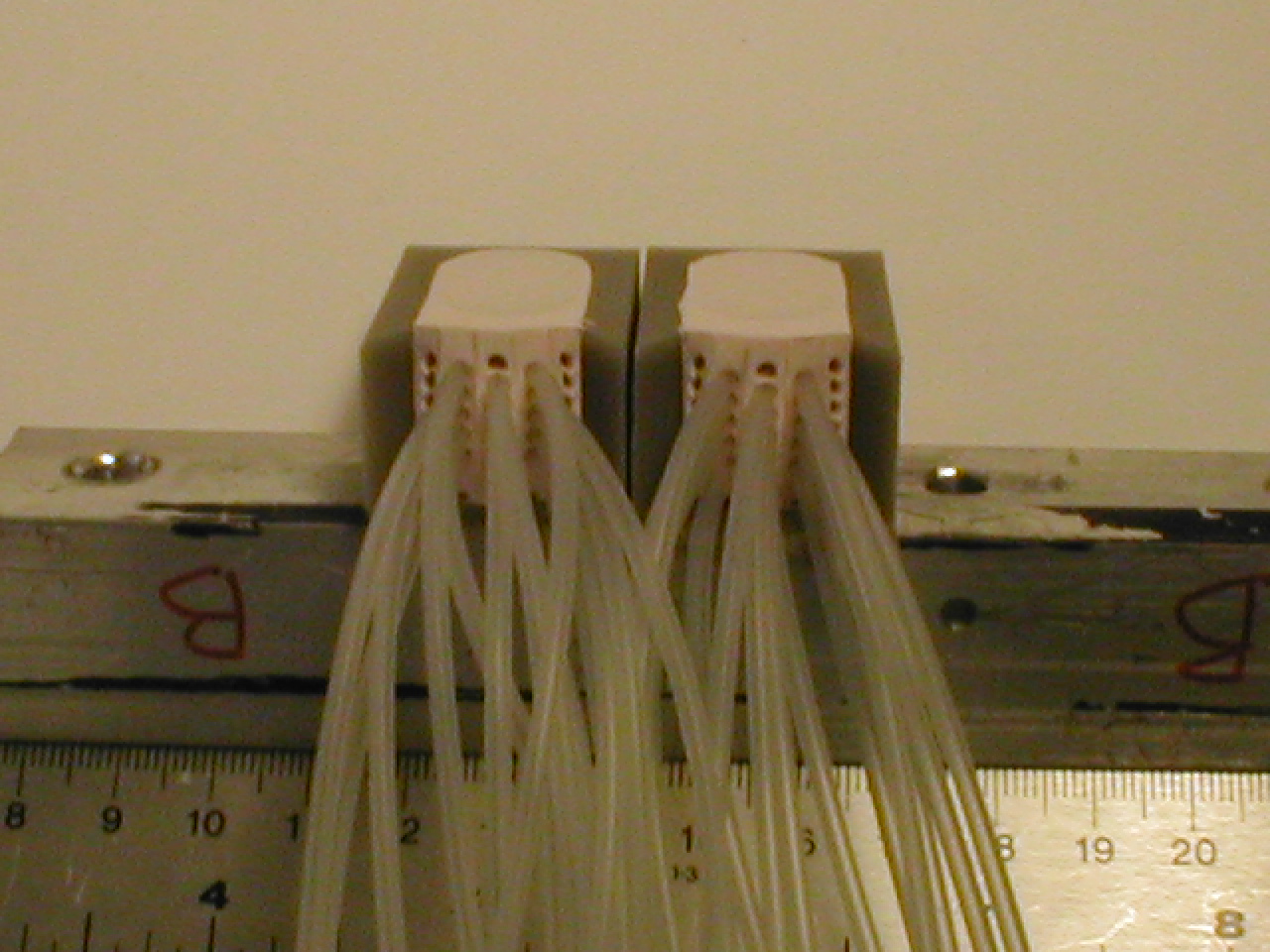

A 14 element display in a 5-4-5 configuration is shown below.

Final Molding

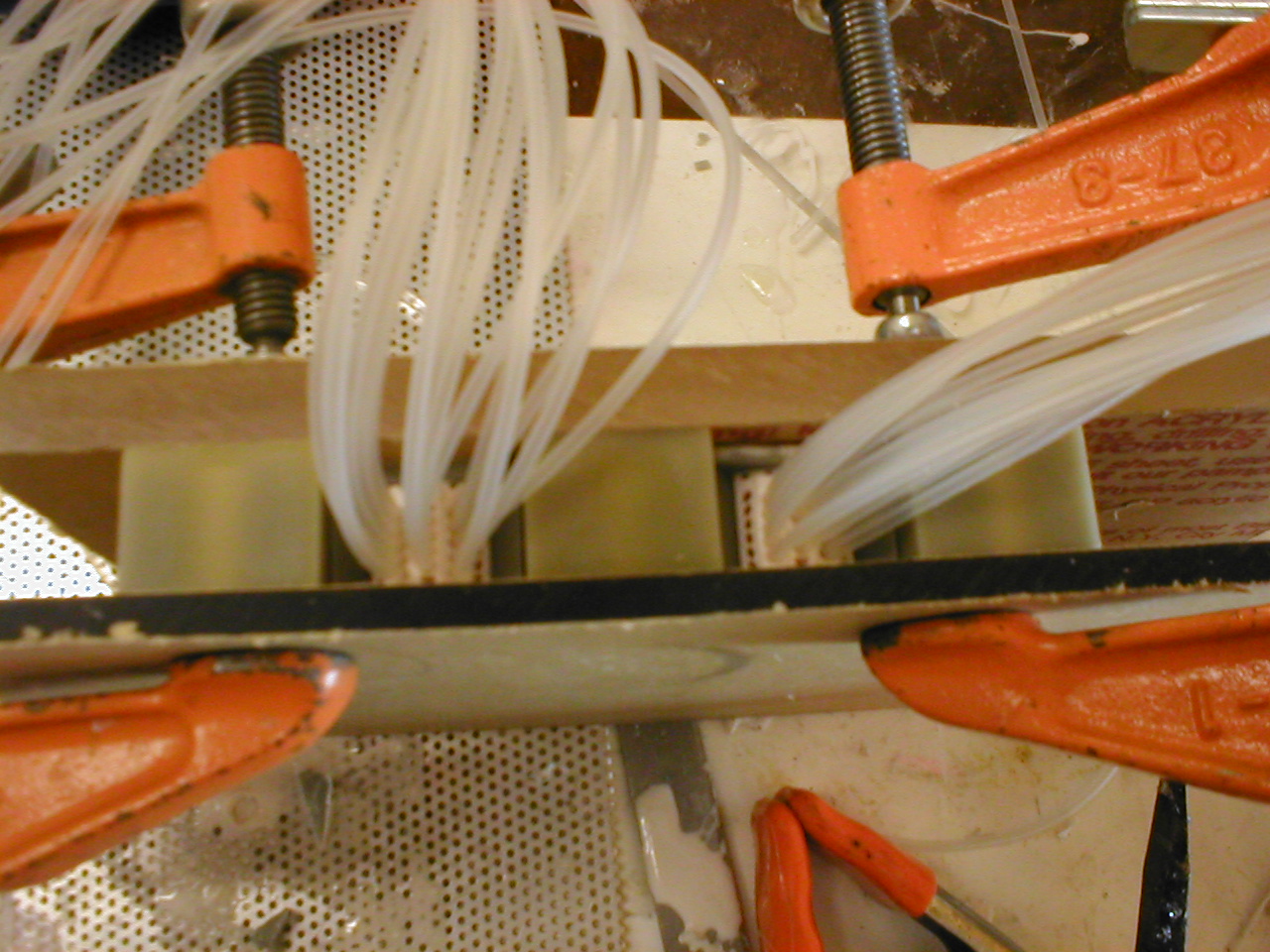

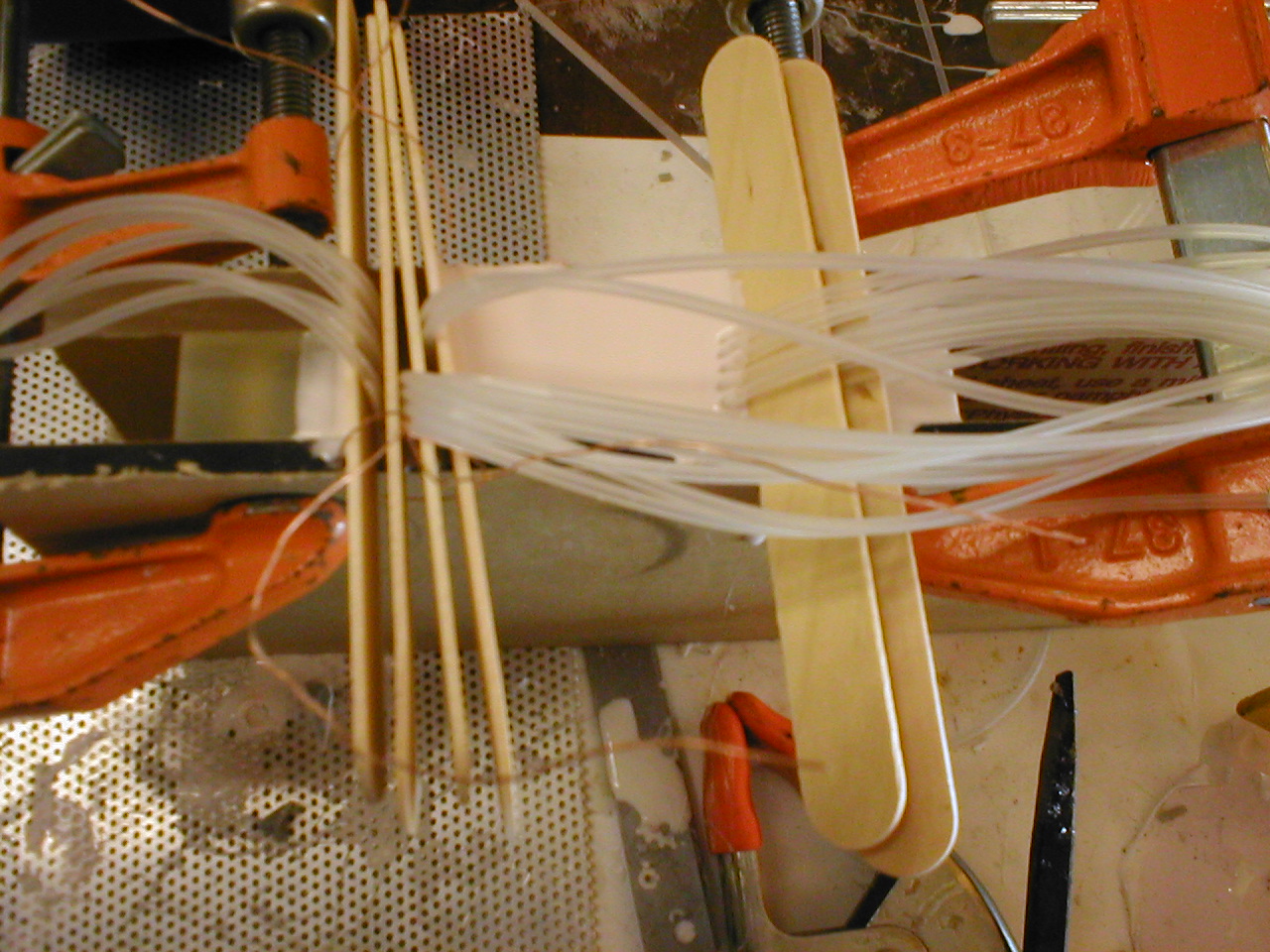

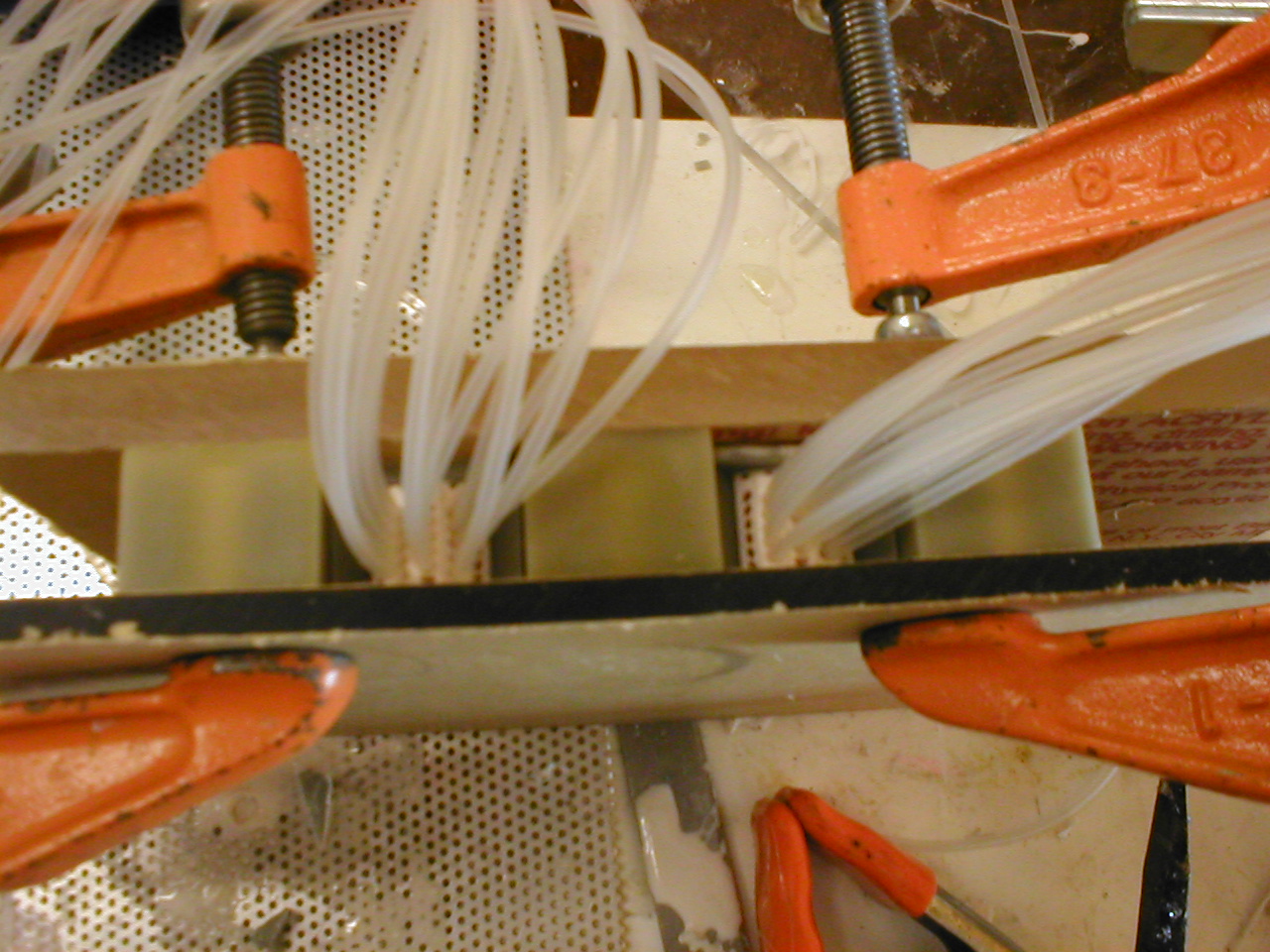

Determine the final mold shape and carefully place the display and tubes

between two plexiglass plates. Use at least

2 mm of rubber to ensure that the tubes stay attached to the display. Use

other base pieces as separators between the displays, if

necessary. Mix some HS II and pour in between the tubes. Do not

vacuum the workpieces as HS II might fill the air chambers.

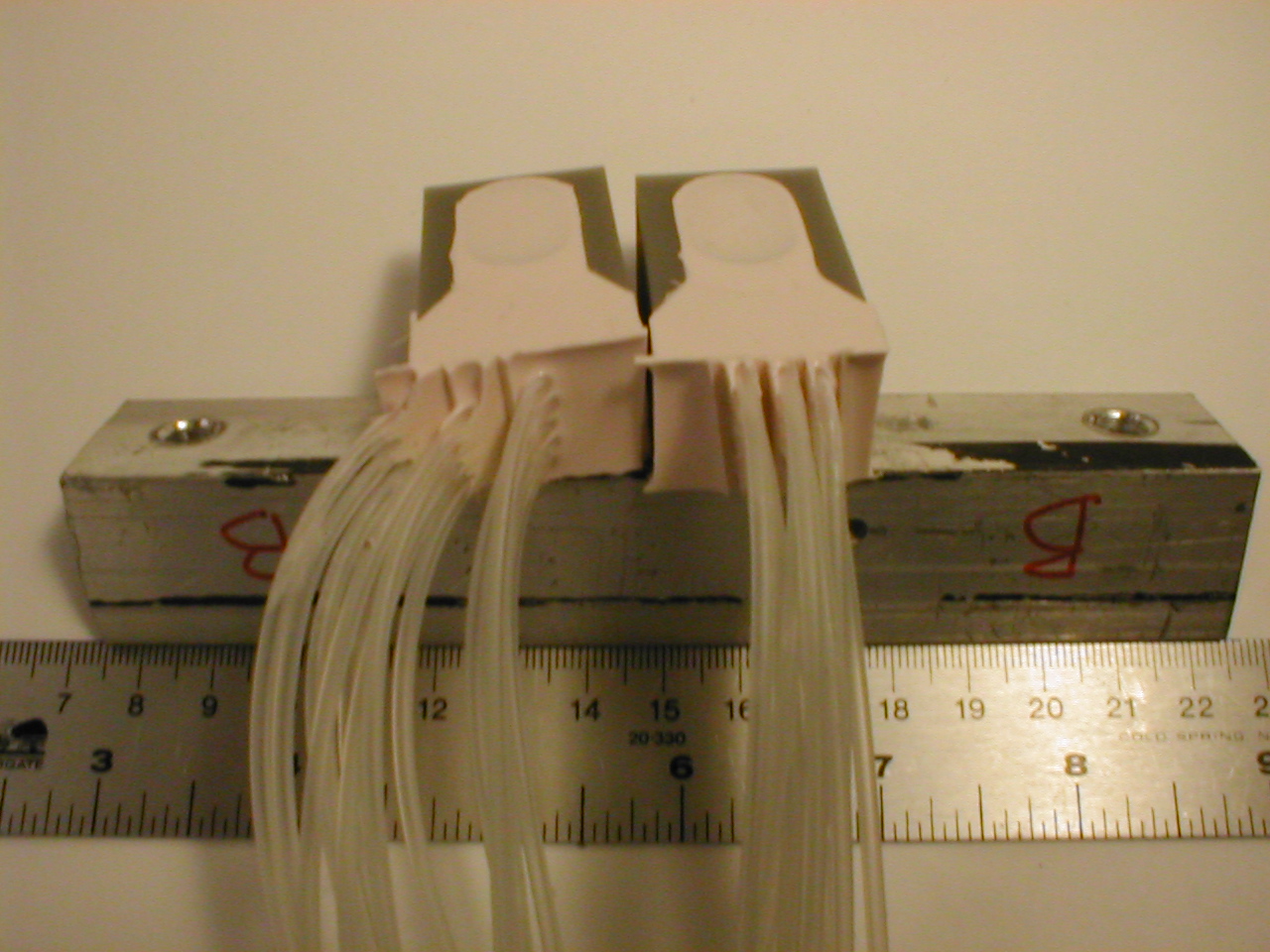

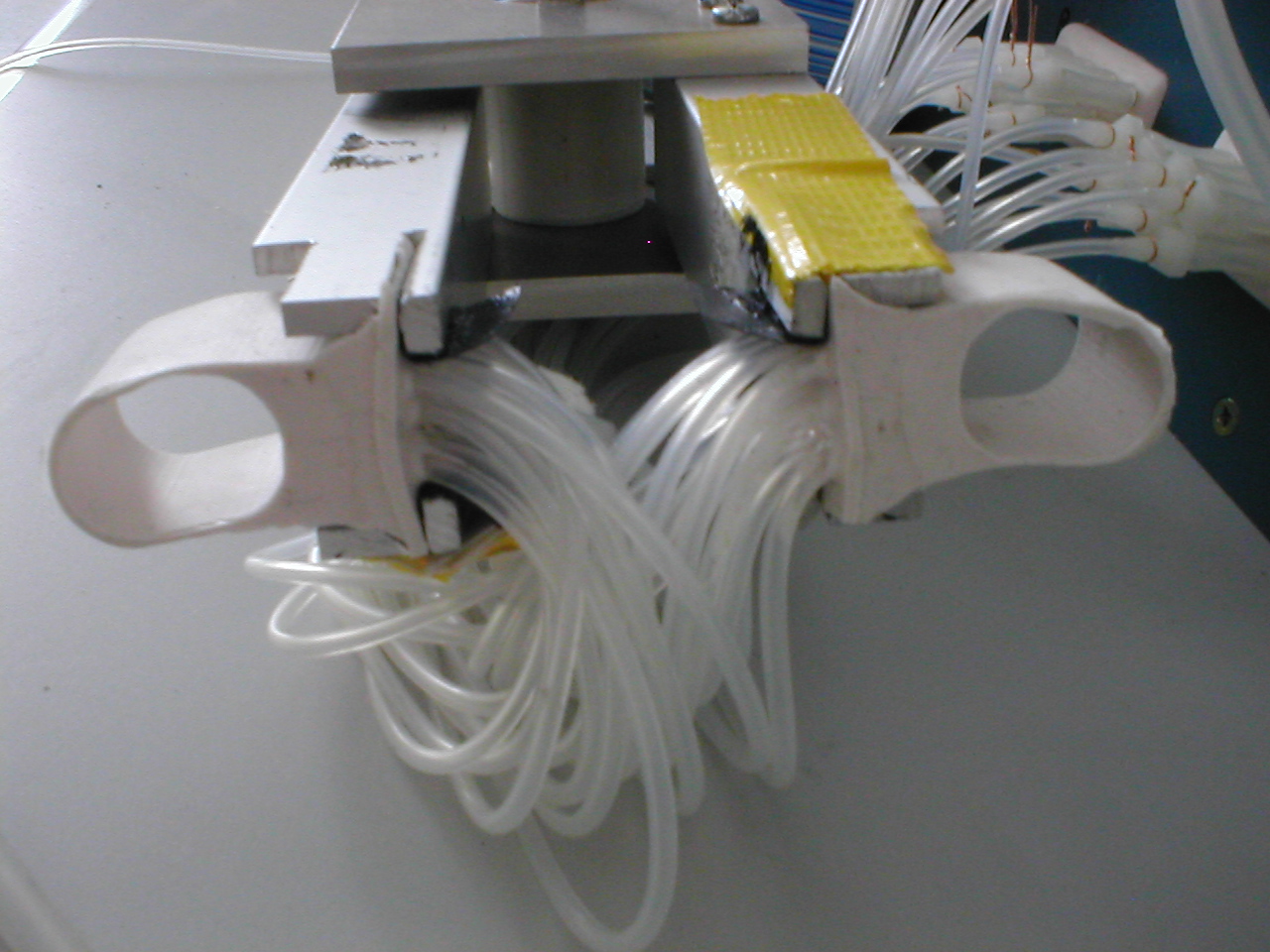

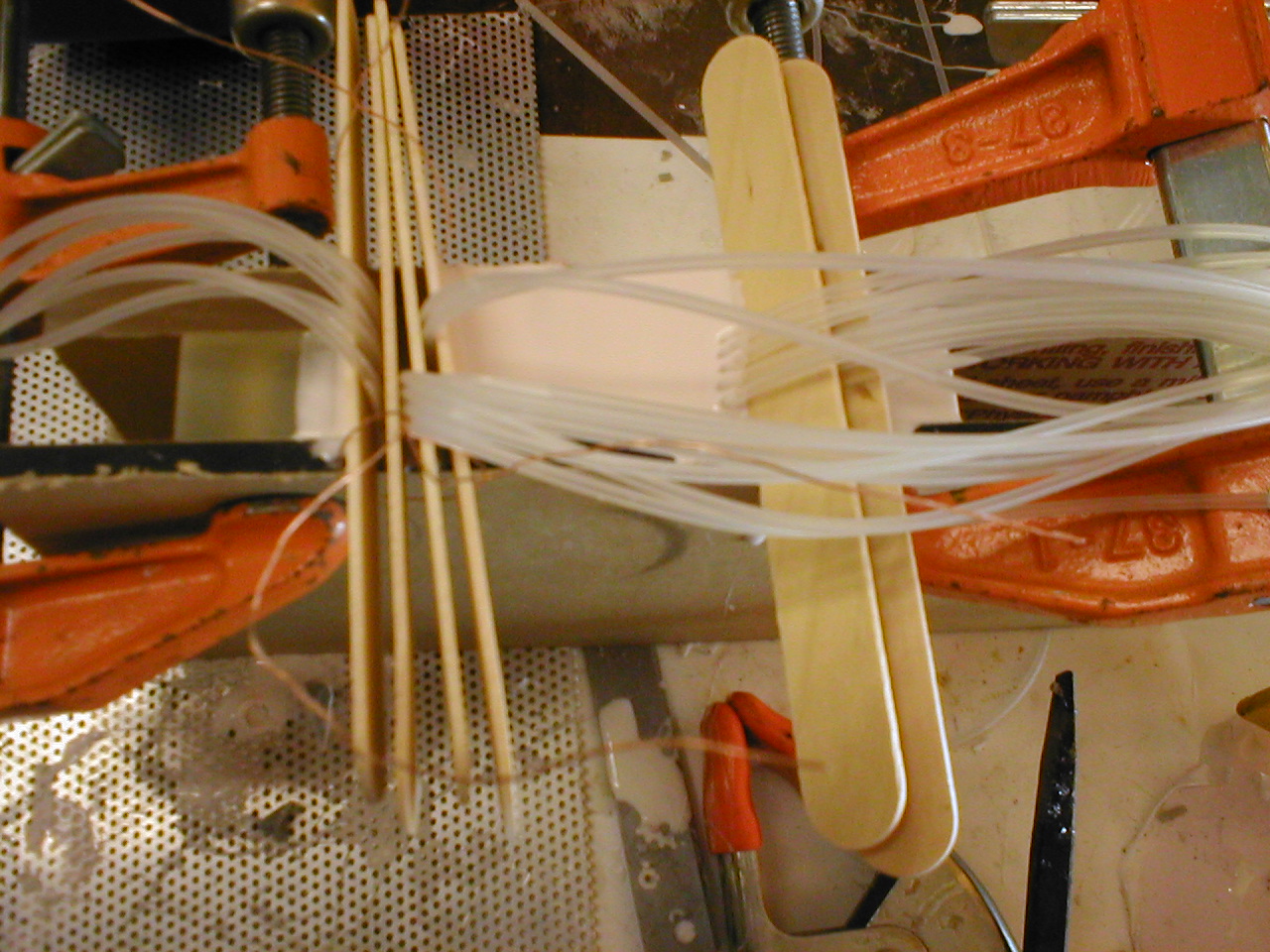

Separate the tubes with tongue depressors as shown below

Let the HS II cure for 24 hours.

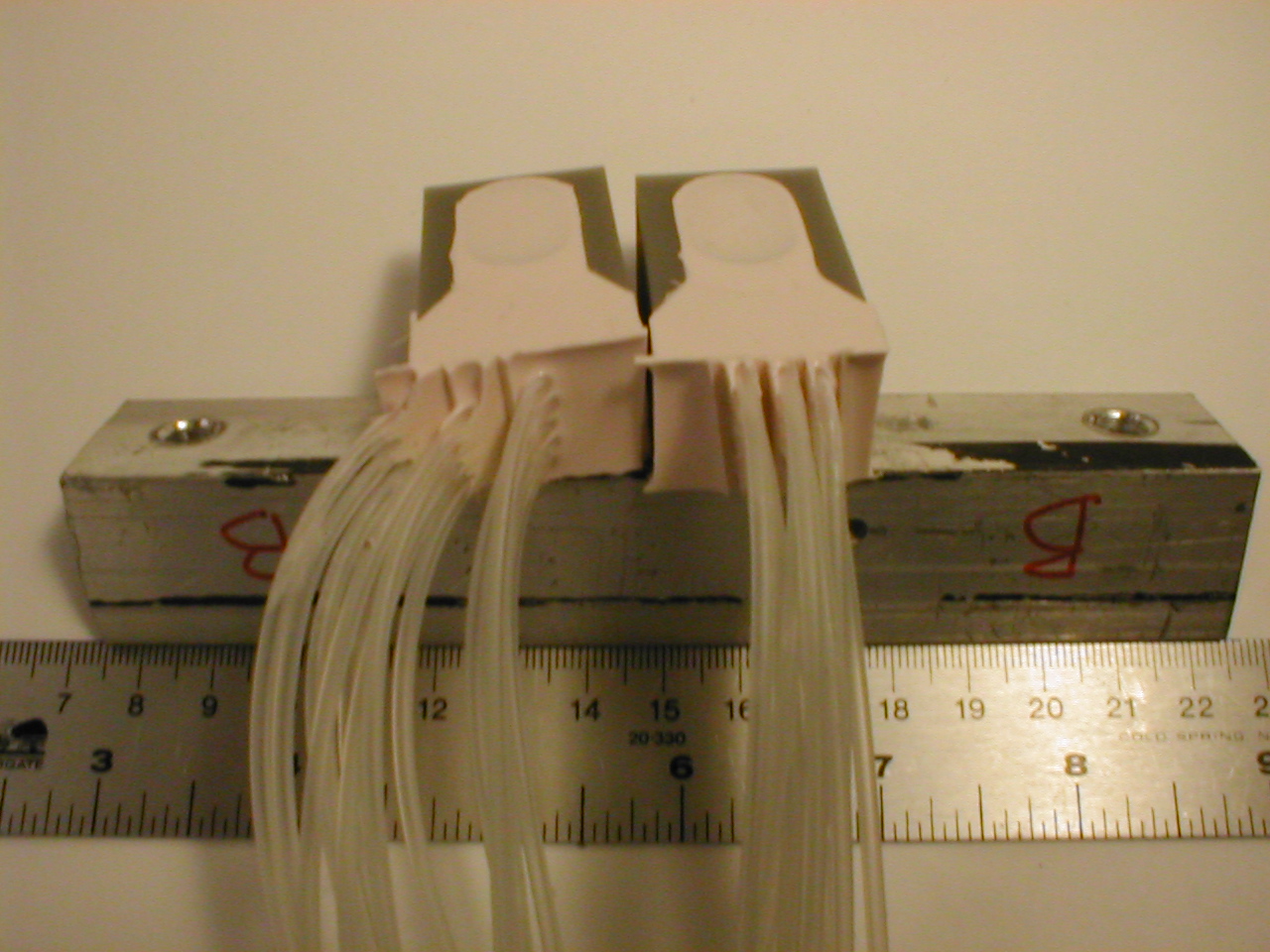

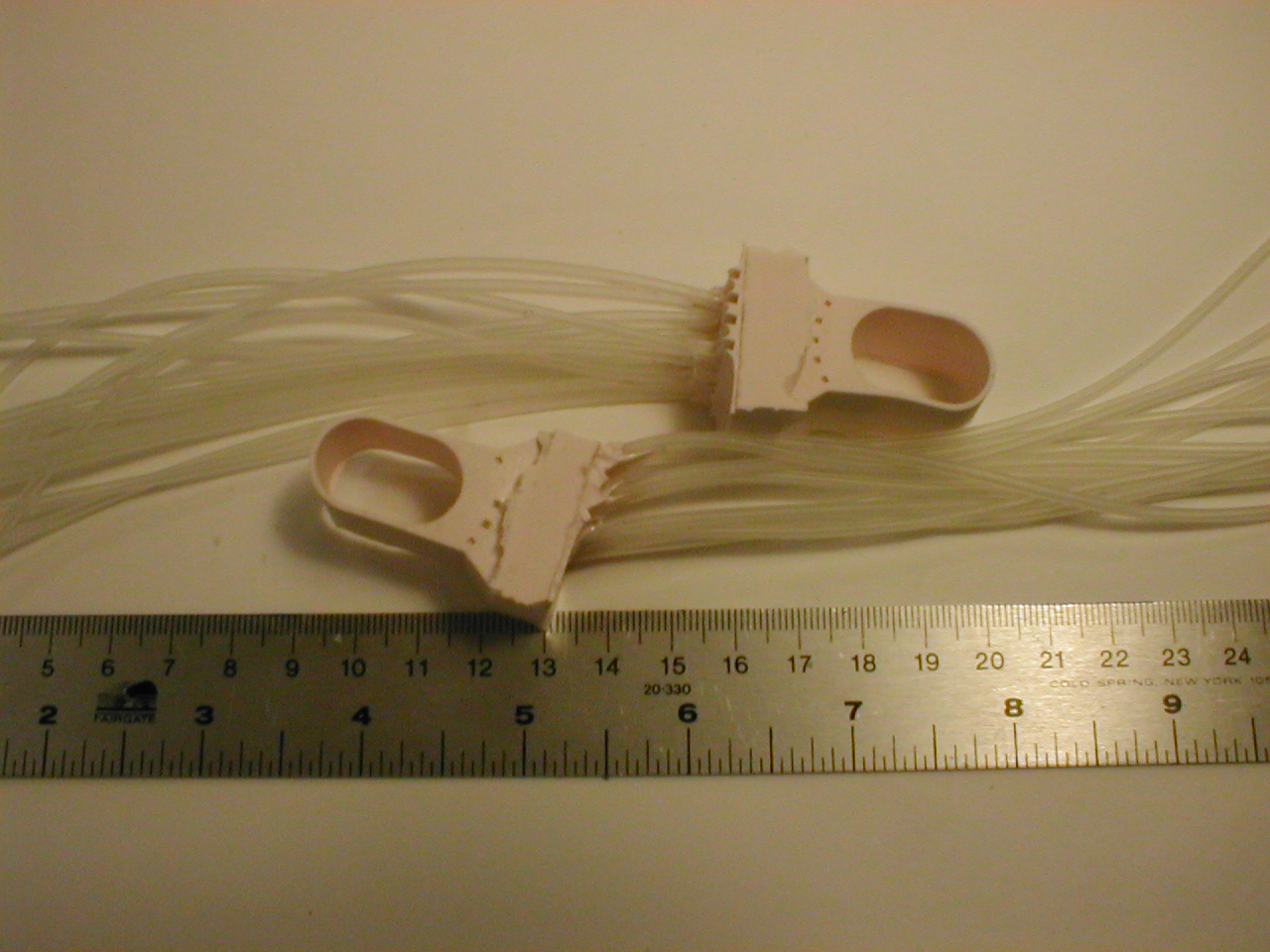

Remove the clamps and release the molds from the plexiglass.

Remove the tactile display from the mold and trim excess rubber.