Stainless

Steel and

Polyester

Kit Parts

Stainless Steel Faceplate

Step 1: 12.5 micron steel should be placed on Gel-pak 4

that is adheared to a glass slide.

Step 2: Cut out the desired pattern with a

laser.

Step 3: The excess steel can then be peeled away leaving just the

faceplate.

Polyester Flexures

Step 1: Cut a small square of polyester of the desired

thickness (e.g. 6 or 12 microns) and place it on Gel-pak 4 that is

mounted on a glass

slide.

Step 2: Cut out the polyester flexure 1mm wide and to the desired

length using the laser.

Alternatively, you can cut out long strips of the poyester with the

laser and store it for future use. When needed, it can then be

cut to

desired length.

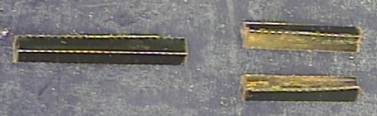

Stainless Steel Beams

Step 1: 12.5 micron steel should be placed on Gel-Pak 4 that is

attached to a glass

slide and

polyimide (PI2525) spin coated on it. The polyimide coating

should be soft baked on a hot plate (a minute with the Gel-Pak and then

the steel piece should be removed from the Gel-Pak and cured alone for

about 30 minutes).

Step 2: The appropiate pattern (cut and score lines) can be applied by

the

laser. Then flip the piece over and spin coat polyimide on the

opposite side the same way as described above.

Step 3: Etch the piece. (This can be done by placing the steel in

a

beaker and pouring a small layer of ferric chloride on top. Then

place the beaker on a hot plate with a magnetic stirrer under a

hood. It is usually finished in a 5 minutes or less depending on

the side of the piece.)

Step 4: The piece can then placed on the folding fixture and

folded. Seal it in place by applying superglue with a thin needle

and running the triangle through a triangular channel. Cut off

the beam and repeat the folding and gluing process for as many beams

that were patterned.

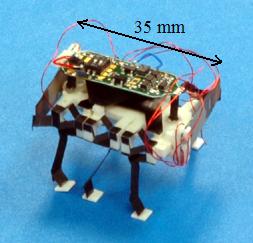

Example Structure Built from these Kit

Parts

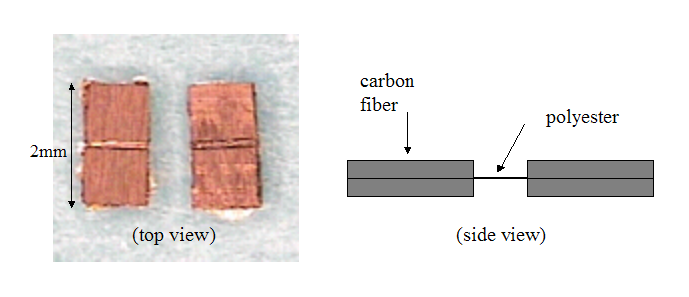

Carbon

Fiber and Polyester Kit Parts

Carbon Fiber Links

Step 1: The uncured carbon fiber can be cut into strips and

stored in

the

freezer until it is ready to be used.

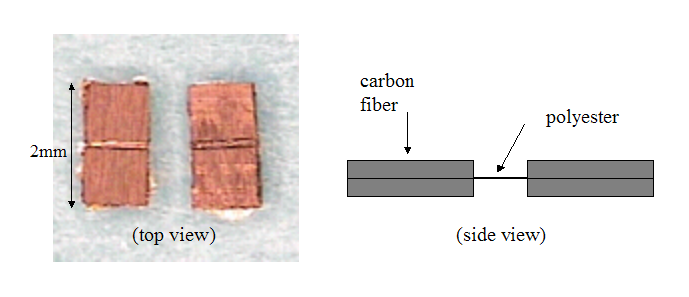

Flexure Elements

Step 1: A carbon fiber layer can be patterned into flexure

elements

under the

laser.

Step 2: Place a layer of polyester on top of the patterned carbon

fiber

layer. Place a teflon layer on top and then a glass slide.

Step 3: Put the assembly in a 150 deg C vacuum

oven with a weight on top to be cured.

Step 4: The same pattern should

then be applied to another carbon fiber layer using the laser.

Step 5: Place the cured polyester and

carbon fiber layer on top of the newly patterned carbon fiber so that

the polyester is in between

the two carbon fiber layers.

Step 6: The whole structure should be cured

in the oven in the same fashion as described in Step 3. When it

is

finished, the individual flexure elements can then be separated easily

with a razor blade.

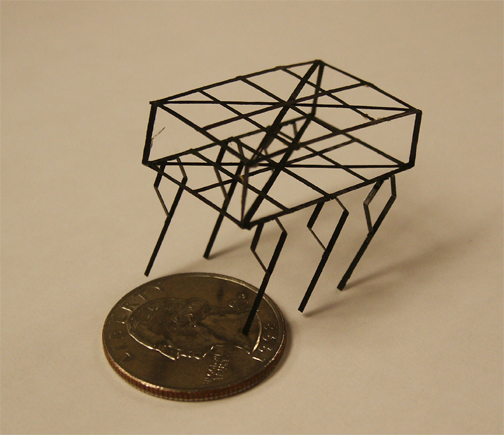

Example Structures Built from Carbon

Fiber/Polyester Combination