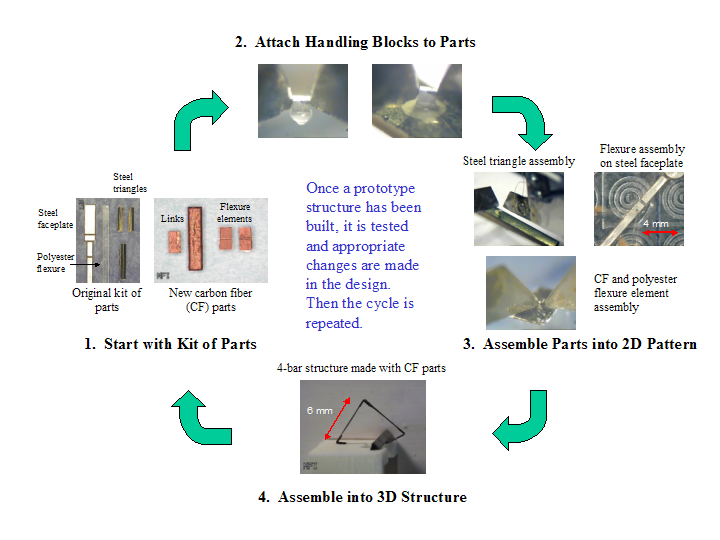

Customizable Pallet and Manipulation of Parts by the Ortho-tweezers (details of steps 2 and 3 above)

- This figure shows a sample pallet containing (from left to right) the handling blocks, low melting point wax, needed kit parts, and final configuration location.

- The Ortho-tweezers are picking up a handling block and dipping it in the low melting point wax.

- The handling block is being attached to one of the parts that need to be manipulated.

- The Ortho-tweezers are reorienting the part and placing in its final configuration.

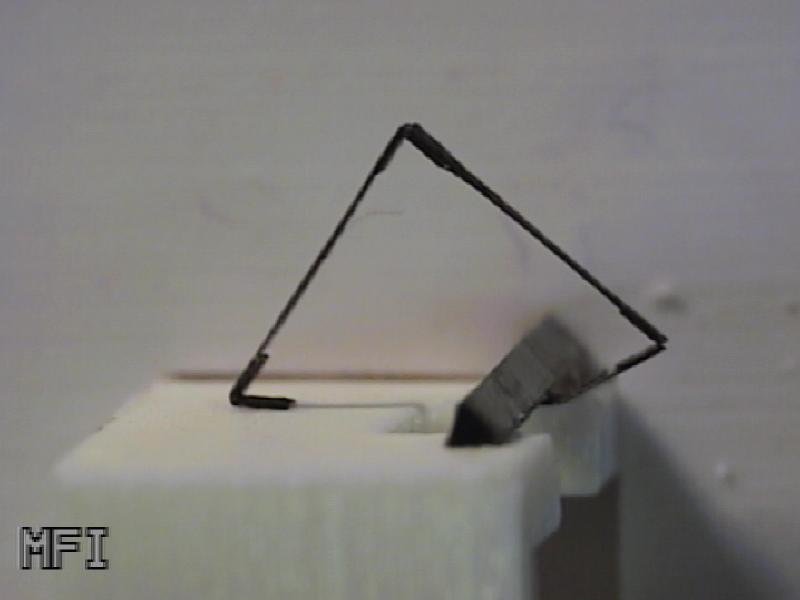

Final Product Examples

|

|

| 4 Bar Mechanism (made with carbon fiber and polyester parts) | 1 Degree of Freedom Wrist (made with stainless steel and polyester parts) |

This research is sponsored by the NSF DMII Program.

``This material is based upon work supported by the National Science

Foundation under Grant No. DMI-0115091. Any opinions, findings and conclusions

or recommendations expressed in this material are those of the author(s)

and do not necessarily reflect the views of the National Science Foundation

(NSF).''