| HOME |

| PUBLICATIONS |

| Biomimetic Millisystems

Lab |

RoACH: A Robotic Autonomous Crawling Hexapod

| The smallest untethered legged robot until 2011* |

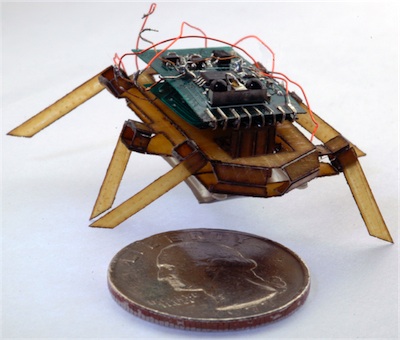

The robot pictured to the right is the Robotic Autonomous Crawling

Hexapod

(RoACH). Fabricated from long fiber-reinforced composites,

this robot makes use of

Smart Composite Microstructures

and integrated shape memory alloy (SMA) wire actuators. In addition to

having novel kinematics that are enabled by the SCM process, all power,

control, and communication electronics are carried onboard and the

entire robot is powered with a 20maHr Lithium-polymer battery from the

Full River corporation. It's capable of walking at about 1 body length

per second (3 cm/sec) for 9.5 minutes.

The robot pictured to the right is the Robotic Autonomous Crawling

Hexapod

(RoACH). Fabricated from long fiber-reinforced composites,

this robot makes use of

Smart Composite Microstructures

and integrated shape memory alloy (SMA) wire actuators. In addition to

having novel kinematics that are enabled by the SCM process, all power,

control, and communication electronics are carried onboard and the

entire robot is powered with a 20maHr Lithium-polymer battery from the

Full River corporation. It's capable of walking at about 1 body length

per second (3 cm/sec) for 9.5 minutes.Hoover IROS 2008 Movie of RoACH |

| The importance of kinematic design |

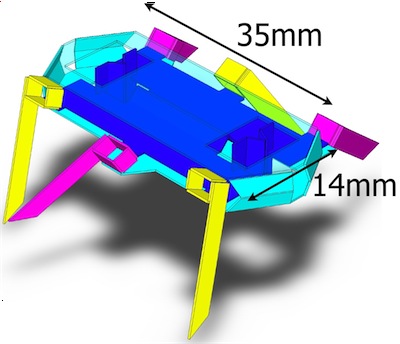

| As

robots get smaller, their design becomes more difficult. In general,

the surface area to volume ratio becomes larger, and this has important

ramifications. Surface forces become large compared to interial forces,

so phenomena such as friction (in bearings or pin joints, for example)

play a more significant role than they did at a larger scale. It also

means that traditional actuator technologies like DC motors are

necessarily less efficient and less power-dense at this scale. The SCM process goes a long way toward addressing these difficulties. It enables the fabrication of complicated, functional folded structures that move using elastic deformation rather than through the use of traditional mechanical elements like pin joints or bearings. It also integrates well with novel actuator technologies like piezo-electric material or shape memory alloy. However, effective, autonomous millirobots using SCM still require skill on the part of the designer to create viable designs that use a minimal number of actuators. Minimizing the number of required actuators minimizes the power required to drive the robot, making it more likely to be capable of sustained autonomy. This design goal therefore forces some of the control of the robot to be integrated into the kinematic design.  RoACH is an example of an autonomous millirobot in which the kinematics of locomotion (an alternating tripod gait, in this case) drove the design of the robot. Pictured to right, RoACH has only two degrees of freedom and is therefore actuated using only actuators. The central blue plate forms a linkage known as the Sarrus linkage. When it contracts, the yellow legs are lifted and the purple legs are lowered. When it expands, the purple legs are lifted and the yellow legs lowered. When the blue plate is moved forward along the long axis of the body (with respect to the outer aqua-colored plates), the yellow legs swing forward while the purple legs swing backward. When it is moved backward, the purple legs swing forward while the yellow legs swing backward. Proper timing of the actuation of these two degrees of freedom allows the robot to walk forward, backward, and even turn. |

| Fabrication |

| RoACH is fabricated using

a version of the SCM process that has been adapted to work with

prepregnated S2 glass fiber reinforced composites. In this process, a

layer of polymer film is sandwiched between laser-micromachined outer

layers of composite and the whole structure is cured. In places where

the composite has been cut away, the polymer layer acts a compliant

hinge, allowing two rigid composite links to bend with respect to each

other. This process enables the creation of complicated folded robot

designs and can even be scaled up to work with inexpensive materials

for scaled rapid prototyping. |

| Power and Control |

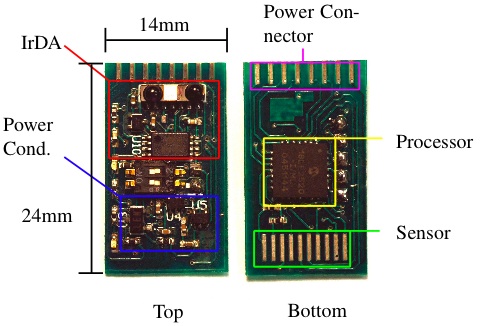

The

RoACH robot is powered using a 20maHr Lithium-polymer battery from Full

River. Control is accomplished with the electronics shown to the right.

The primary components of the board are a 10Mips PIC LF2520

microprocessor and an IrDA communication module for wireless

communication with a PC. The

RoACH robot is powered using a 20maHr Lithium-polymer battery from Full

River. Control is accomplished with the electronics shown to the right.

The primary components of the board are a 10Mips PIC LF2520

microprocessor and an IrDA communication module for wireless

communication with a PC. The power electronics are pictured on the left and consist of a standard boost converter topology for increasing the battery voltage to the level necessary to provide sufficient current to heat the SMA wire actuators. |

| Performance |

RoACH weighs: 2.5 grams Dimensions: 35mm long x 14 mm wide x 13 mm tall Maximum walking speed: 1 body length (3cm) per second Maximum battery life: 9min 30secs Specific power: 15mW/mms-1 For more details see the conference paper on RoACH. |